Ex-Demo Haas CNC

We are restocking our UK showrooms, and our current Haas CNC display machines are now available for purchase as Ex-Demo units, offering you significant savings!

Significant savings • Full warranty

These machines have been used only for showroom demonstrations, so they come with very low operating hours and have the full Haas warranty. They are available now for fast delivery.

We also provide competitive trade-in deals for your old Haas CNC, regardless of its age.

Call 01603 760539 or email sales@haas.co.uk for more information.

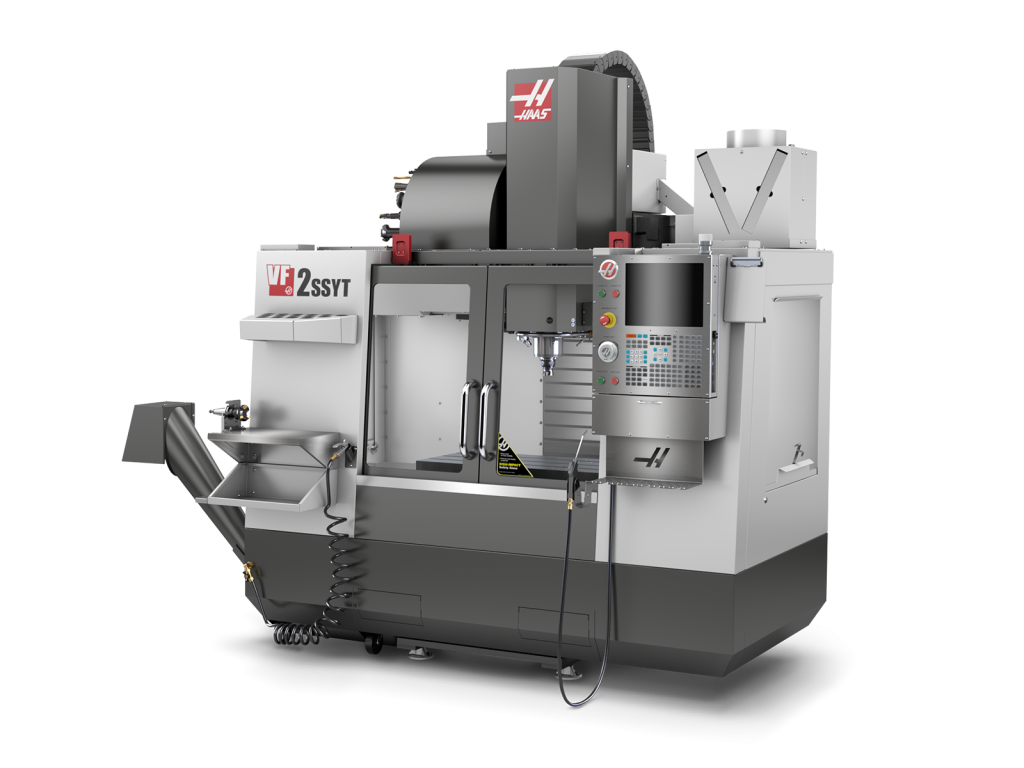

VF-2SSYT

Super Speed VMC-

• 762 x 508 x 508 mm

-

• 12,000 rpm

-

• 30+1 side mount changer

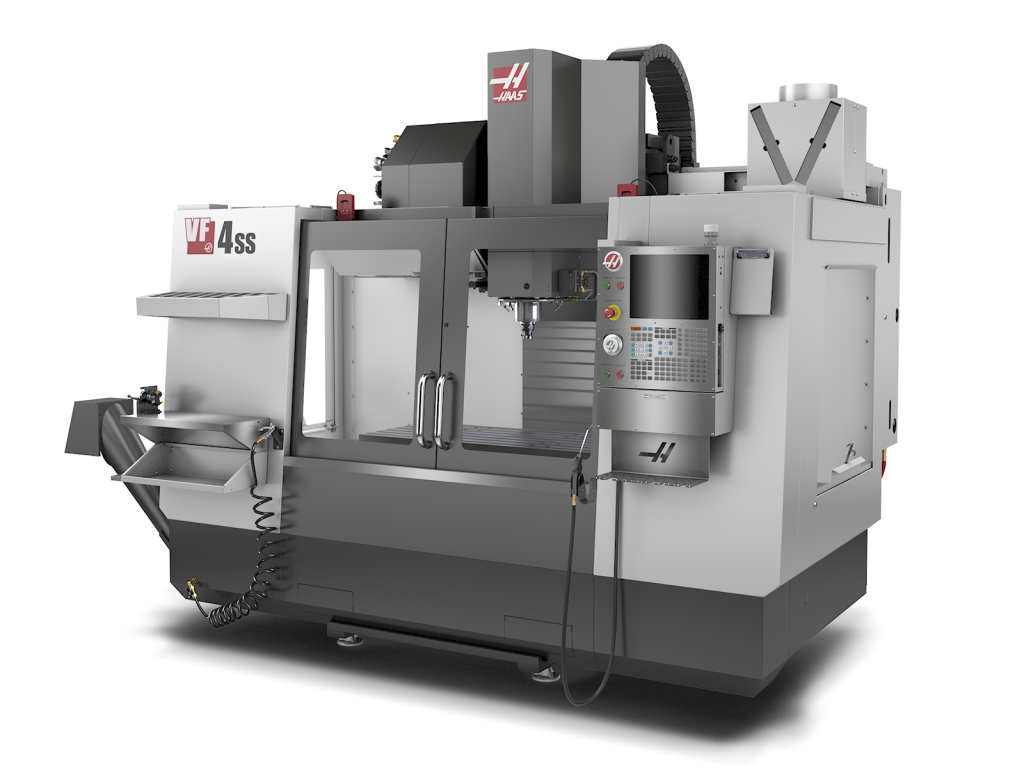

VF-4SS

Super Speed VMC-

• 1270 x 508 x 635 mm

-

• 12,000 rpm

-

• 30+1 side mount changer

VF-6SS

Large Capacity VMC-

• 1,626 x 813 x 762 mm

-

• 12,000 rpm

-

• 30+1 side mount changer

SUPER MINI MILL

New Model + APL Available-

• 406 x 356 x 381 mm

-

• 10,000 rpm

-

• 30+1 side mount changer

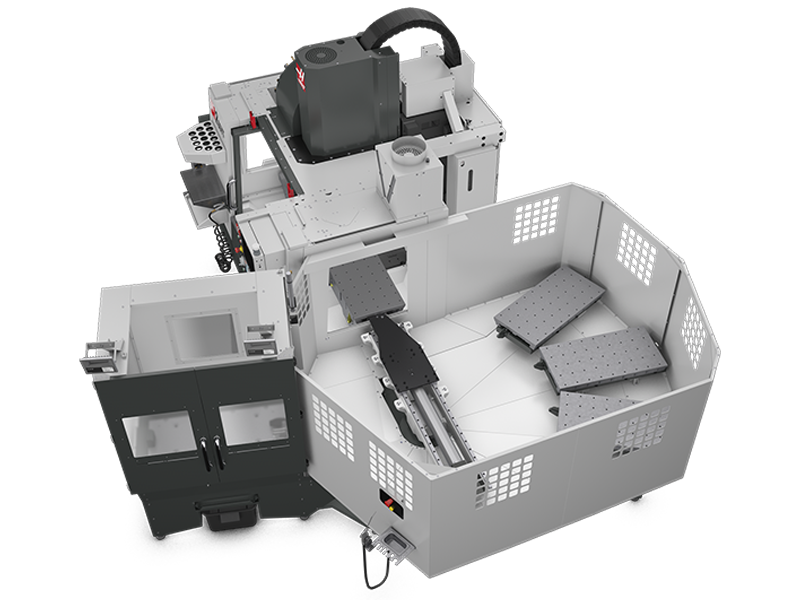

PALLET POOL

VF-2SSYT + Pallet Pool-

• 3+1 Stations

-

• 914 x 457 mm pallet size

-

• 340 kg max part weight

UMC-500

5-Axis UMC-

• 15,000 rpm spindle

-

• 50+1 side mount changer

-

• 400 mm platter

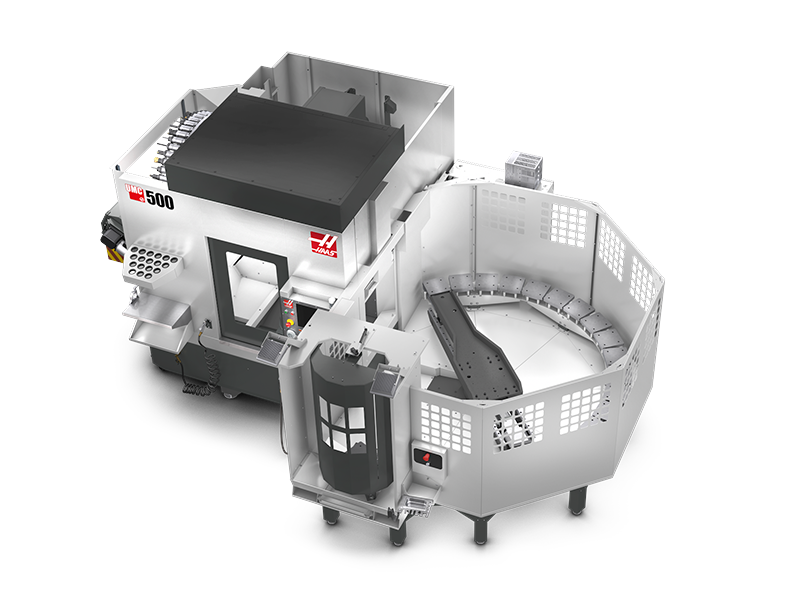

PALLET POOL

UMC-500 + Pallet Pool-

• 10+1 stations

-

• 406 mm max part diameter

-

• 90 kg max part weight

UMC-750

5-Axis Universal Machine-

• 762 x 508 x 508 mm

-

• 15,000 rpm

-

• 50+1 side mount changer

TM-0P

CNC Toolroom Mill-

• 508 x 305 x 406 mm

-

• 6,000 rpm 40-taper

-

• 10 Pocket ATC

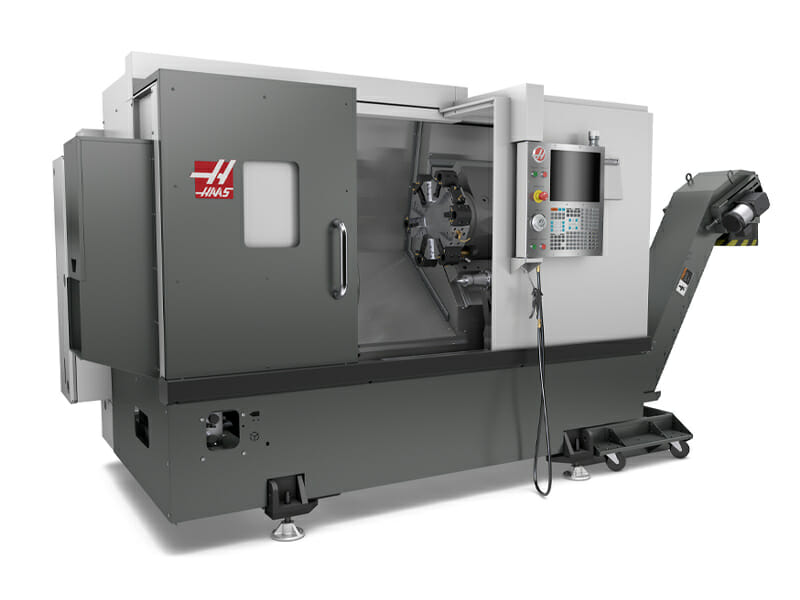

ST-25Y

Y-Axis Turning Centre-

• 254 mm chuck

-

• 76.2 mm bar capacity

-

• 12 station BMT65

ST-28Y

Y-Axis Turning Centre-

• 305 mm chuck

-

• 102 mm bar capacity

-

• 12 station BMT65

DS-30Y

Y-Axis Dual Spindle-

• (D) 349 mm x (L) 826 mm

-

• 76.2 mm bar capacity

-

• Dual Spindle

Please send me details of the ex-demo machines

Do you need funding?

Talk to our dedicated team

Haas Financial Services can find you the most competitive funding options from our extensive portfolio of funders.

Navigating your way through the different forms of lending banks and companies have to offer can be hard.

Get in touch and we’ll be able to help you find the perfect option to finance your business and let you take the next step.

For more details on finance packages, please call 01603 227838 or email: finance@haas.co.uk