Home / Videos & More / Our Customers / Motorsport / Ecurie Bertelli

Ecurie Bertelli - the pre-war Aston Martin specialists

Ecurie Bertelli are passionate about pre-war Aston Martins. The company, based in Olney, Buckinghamshire, traces its roots back to Morntane Engineering, founded by Pink Floyd drummer Nick Mason, a man with a great passion for these iconic cars. The team has specialised in this area throughout its 45-year history. Ecurie are considered the experts in pre-war Aston Martin motor car sales, care, repair, restoration, conservation, and race event support worldwide.

Managing Director Robert Blakemore explains the Ecurie Bertelli ethos, which echoes that of Aston-Martin pre-war; “It must be light, simple and fast, as well as ultra-reliable.”

Reliability is a necessity; the cars often cover hundreds of miles before their race even begins. “We had a client who drove 1,500 km from Belfast to Mantova in Italy and completed a 1,000 km rally before driving his Aston back to our factory. We then race-prepped it, and it was back out on the track the following weekend.

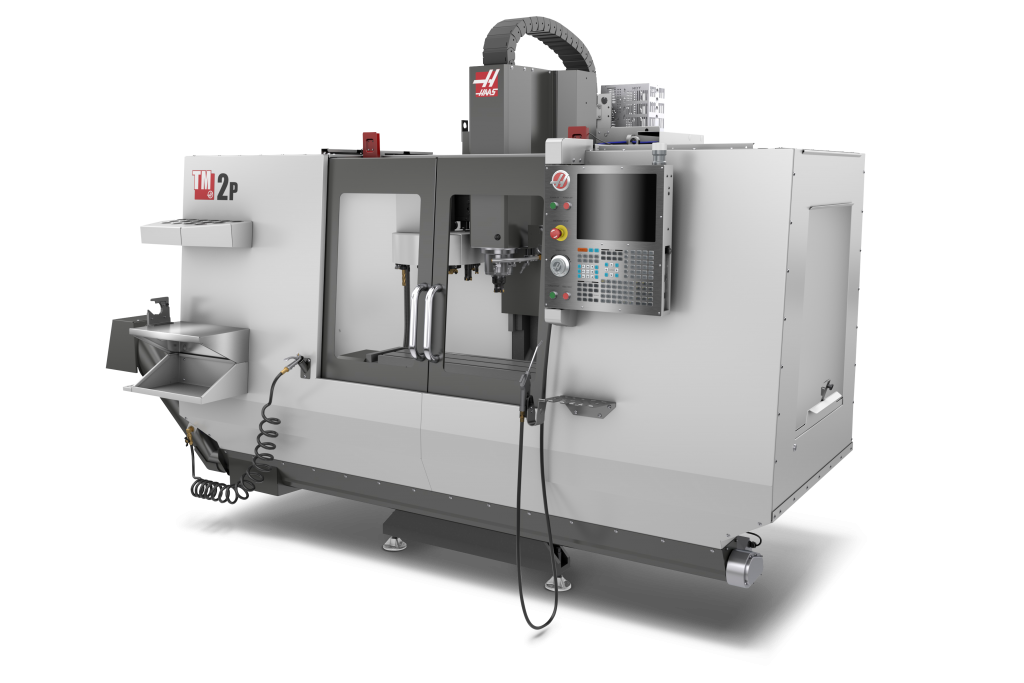

The majority of replacement parts were historically manufactured on-site, using manual mills and lathes, but the machines’ limitations on tolerances meant that some components had to be outsourced. In 2019 Robert decided to make a change. He contacted Haas, who organised a visit by their local salesman. “Haas assessed the type of work we were doing and recommended a TM-2P Toolroom Mill.” The TM-2P has a 7.5 hp, 6,000 rpm spindle and ten pocket carousel-style tool changer.

“The machine was installed with no fuss, and combined with our training and ongoing support the whole experience has been a pleasure. The transition from manual to CNC has been a very successful one. It has been a great challenge for us, but Haas has supported us very well.

“The speed in which we make parts has improved, as has the repeatability. Our work is typically small batches, but we will repeat them year after year, so repeatability over time is key. Ecurie’s investment will pay us back over and again.”

Simon Boreham joined Ecurie Bertelli as an apprentice and is now an engineer. “By machining our parts on the Haas TM-2P we don’t have to fettle them anymore as the accuracy is so much improved. The programming seemed a steep learning curve, but after the training with Haas, we were quickly cutting parts. They helped us get the hang of the Autodesk CAD/CAM system and the layout of the Haas control is very clear; it takes you straight to the tool offsets and shows you what to do.”

The team has a comprehensive archive of 2D hand drawings from the 1930s, from which they make CAD models. “Now, we load up a program from file and make a part. But, of course, we’re still learning, and if we have an issue, there is always someone at Haas on the end of the phone to help out, or they come down to see us if we need it.”

Robert explains why he chose Haas; “We felt confident with the initial consultation that we were being listened to and that the machine would deliver for us. It’s a brand we can grow with and one that will support us for many years to come. Haas has given us the right tools for the job.”

“We felt confident with the initial consultation that we were being listened to and that the machine would deliver for us. It’s a brand we can grow with and one that will support us for many years to come. Haas has given us the right tools for the job.”

Robert Blakemore – Managing Director