Wireless Intuitive Probing System

WIPS - Take your production to the next level

Reduce setup times without having to know G-code or macro programming

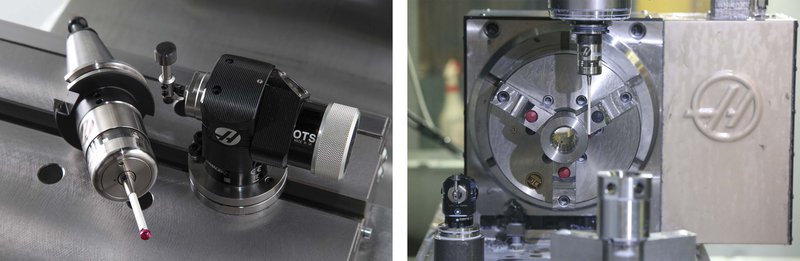

Set up your Haas mill up to 5 times faster using our Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting probe, and optical machine interface, along with powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates. WIPS allows you to quickly and easily define work offset coordinates, set tool length offsets, and perform in-process inspection, for both part inspection and tool breakage detection. WIPS is the single best productivity improvement you can add to your Haas mill.

The Haas Wireless Intuitive Probing System (WIPS) guides the operator through the job set-up process with easy-to-use templates. The templates help reduce setup time during by allowing the operator to multitask while the automatic probing routines are running. WIPS can also ensure that parts and tools are maintained within tolerance throughout the production process, by using the available wear and break-detection routines. WIPS has the ability to define work offset coordinates, set tool length offsets, and perform in-process inspection within the program.

Drastically reduce setup times with this complete probing package

Get more work done

Setup reduction is critical to maximizing the productivity of any machine tool. With the probing solutions available from Haas, any machine can be set up in minutes, with just a few button pushes. Our industry-leading Wireless Intuitive Probing System (WIPS) sets the standard for integrated probing systems. Easy on-screen directions guide beginning users through the process. Experienced users have access to the full power and capabilities of custom probe routines.

WIPS includes:

- Wireless Spindle Probe (work probe)

- Wireless Tool Setter (tool probe)

- Optical Machine Interface (OMI)

- User-Definable Macros

- Spindle Orientation

- Coordinate Rotation & Scaling

- Visual Part Programming System (VPS)

Video - Option spotlight

Meet your new setup machinist

The Haas Wireless Intuitive Probing System (WIPS) does a lot more than you think. Not only does it allow you to easily set work and tool offsets, WIPS can also check if your parts are loaded correctly, inspect your parts in-process on the machine, and detect broken tools. This is one option you will never second-guess ordering on your next machine.

Video - Haas Tip of the Day

tool offsets

Have you ever looked at the tool offset screen on your Haas mill and wondered what all those columns are for? In this Tip of the Day, Mark covers the topic in detail, giving you all the answers. Whether you set your tool offsets manually or with a probe, anyone who programs or operates a machine needs to watch this video.

Video - Haas Tip of the Day

Use WIPS to set work offsets

Anyone who has run a machine knows how long it takes to set work offsets. What if you could do it in a fraction of the time? It turns out you can, and it’s easier than you think! Watch as Mark walks you through the process of setting your work offsets using a probe and learn a few other probing tips along the way.

Video - Mistake proof with WIPS

Mistake Proof Your Setup with Probing

That’s right! Mark’s finally back. He’s been super busy with show presentations and lots of development projects here at the factory. But we finally wrestled him free to get back to making great videos! In this TOD, Mark shows us how one simple code can open up possibilities for adding a Poka-Yoke into your program. What is that? Click play to find out!