CL-1

Ultra-compact CNC chucker lathe

Ultra-compact CNC chucker lathe

Maximum Capacity: 305 mm x 305 mm

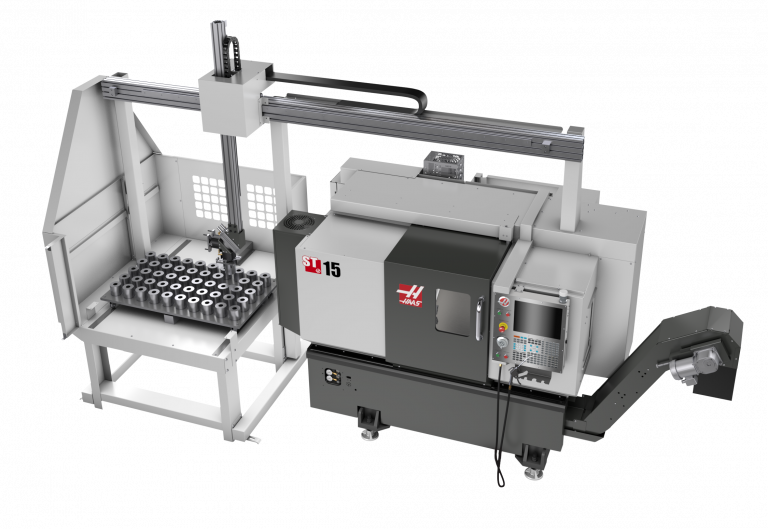

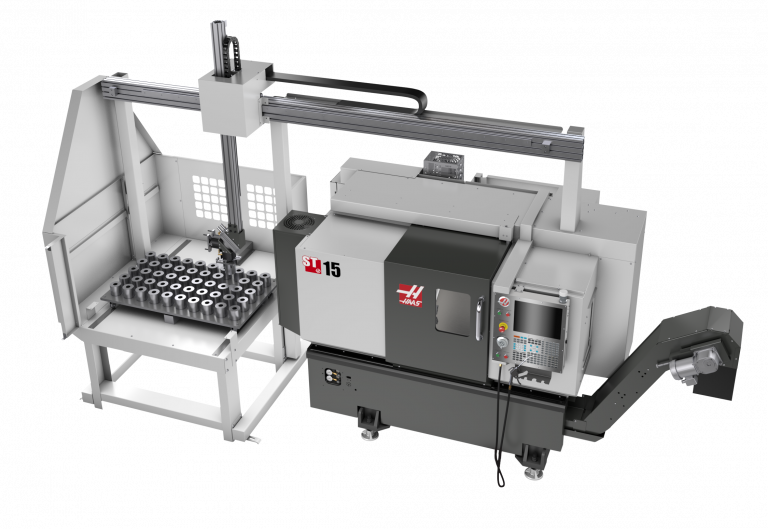

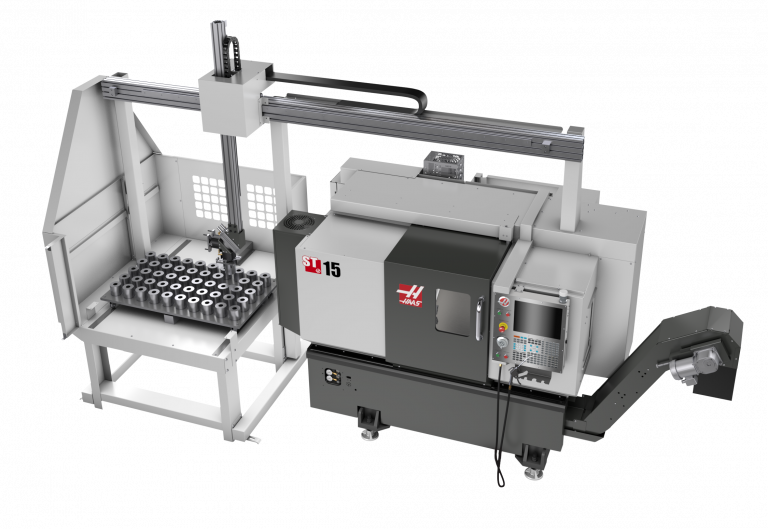

For ST series lathes up to ST-25

Haas Bar Feeder – Automate part production

Maximum Capacity: 305 mm Diameter 826 mm Length

Maximum Capacity: 406 Diameter 762mm Length

Maximum Capacity: 305 mm x 305 mm

Maximum Capacity: 330 Diameter 533mm Length

For ST series lathes up to ST-25

Maximum Capacity: 330 Diameter 1080 mm Length

Haas Bar Feeder – Automate part production

Maximum Capacity: 305 mm Diameter 826 mm Length

Maximum Capacity: 330 Diameter 533mm Length

Maximum Capacity: 381 mm Diameter 826 mm Length

Maximum Capacity: 349 Diameter 1,588 mm Length

For ST series lathes up to ST-25

Maximum Capacity: 330 Diameter 1080mm Length

Haas Bar Feeder – Automate part production

Maximum Capacity: 406 Diameter 1219mm Length

Maximum Capacity: 330 Diameter 533mm Length

Haas Bar Feeder – Automate part production

Maximum Capacity: 381 mm Diameter 826 mm Length

Maximum Capacity: 381 mm Diameter 1,588 mm Length

For Example: When a rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. We have labeled this particular rotary and mill combination with a yellow caution

You can design and build your own sub-plate using the dimensions of your Haas mill and the dimensions of the rotary you'd like to use on that mill. Product dimensions are available for every machine and rotary on this website.

Single-Head Rotary Tables and Indexers are usually mounted to the right side of the table, with the rotary facing the centre of the machine. This is the basic setup we used to determine the fit of your rotary product.

Image shown for mounting example purposes only. Your actual rotary and mill appearance may differ.

Trunnion Tables, T5Cs, and TRTs are usually mounted in the centre (or slightly off-centre) of the mill table. If you are using probing on the mill, be aware of the interference with larger tools, especially during tool changes.

NOTE: Trunnion units present interference issues with the swing of the unit relative to the machine column and spindle head.

Image shown for mounting example purposes only. Your actual rotary and mill appearance may differ.

Multi-Head Rotary Tables and Indexers are usually mounted toward the back of the table, with the indexer heads or platter facing forward. To mount a multi-head rotary in a different orientation, you must use alternative fixturing.

Image shown for mounting example purposes only. Your actual rotary and mill appearance may differ.

Important Information:

4-axis machines cannot use dual-axis rotaries.

Some options may affect mounting (EC-1600 4th-Axis Table, Low-Profile Tables, Table Spacers, Column Risers, etc.

Tool Changers: SMTCs and umbrella tool changers both present interference issues, plan appropriately.