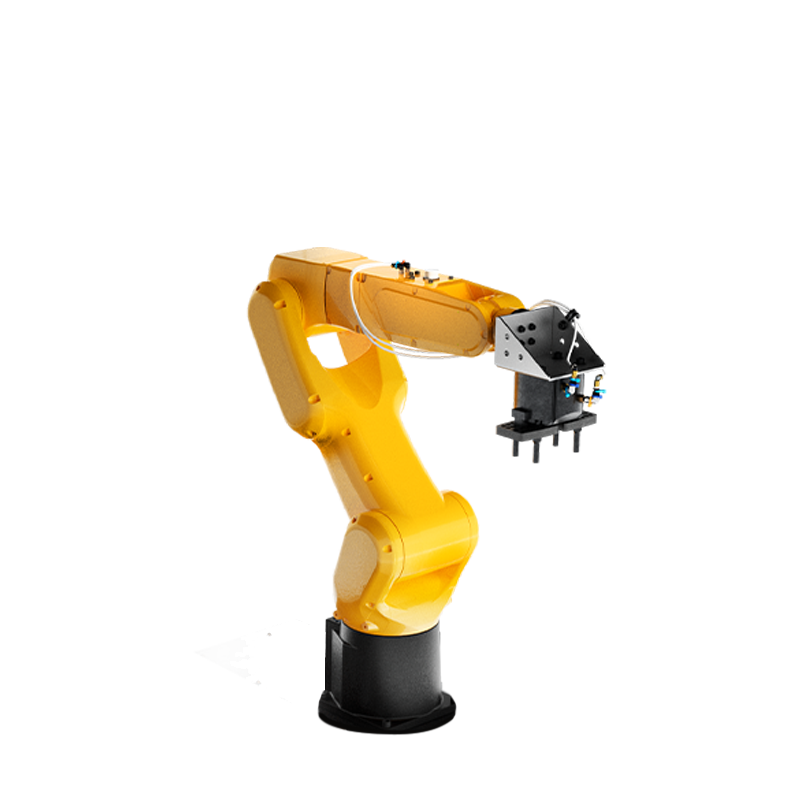

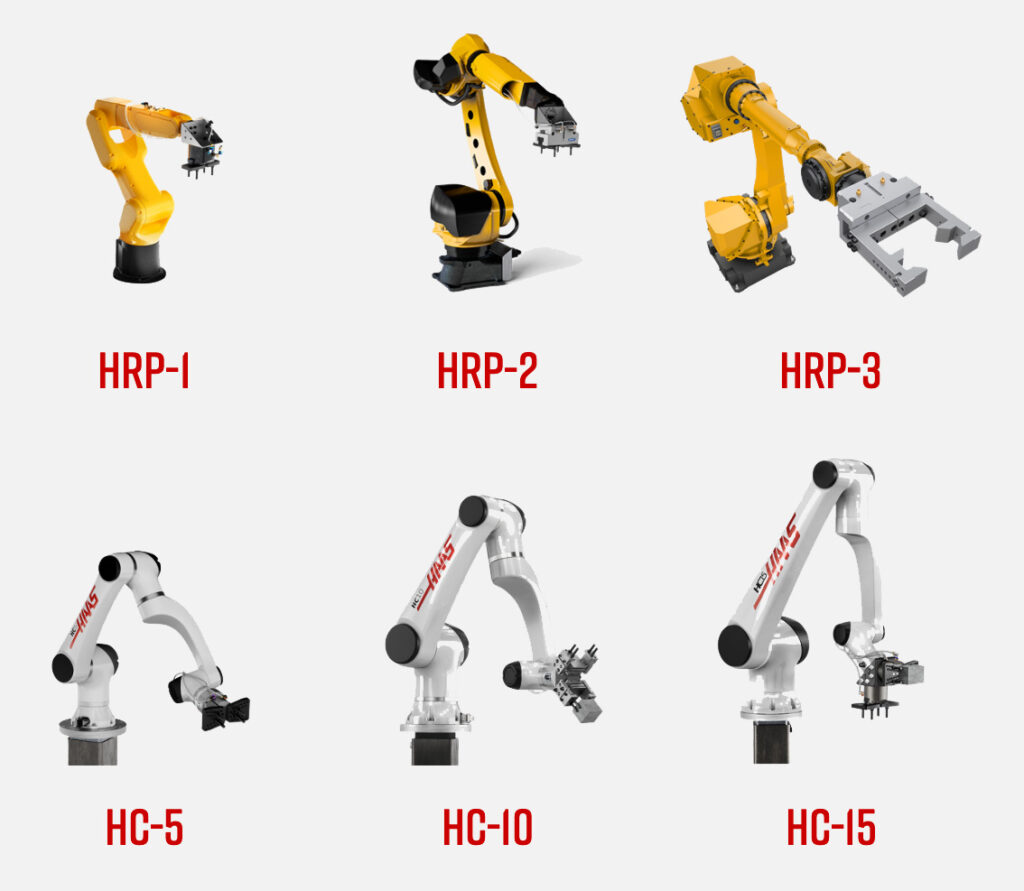

HRP-3 Robot

50 kg

Capacity

307 mm

Max Part Dia.

2050 mm

Reach

6

AXIS

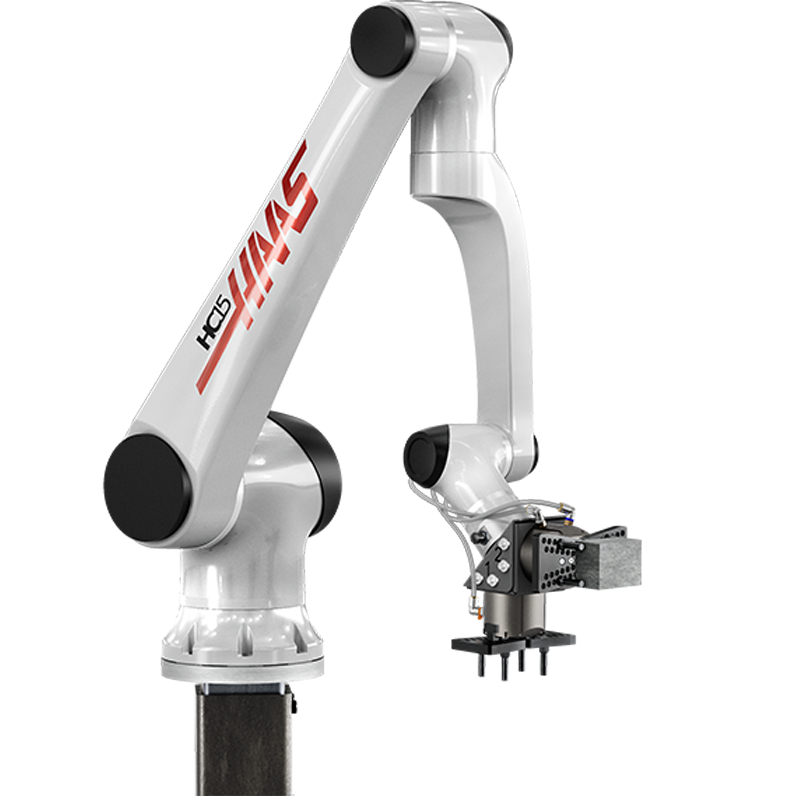

The Haas Robot Package 3 is a fully integrated, plug-and-play, 50 kg capacity robot system for Haas machines. The system is controlled entirely from the Haas control. Includes: 6-axis robot, software interface for direct control through the Haas machine, electrical interface box, safety guarding, and all necessary solenoids, hardware, and cables.

50 kg Max Capacity (part + gripper)

- All-inclusive design, with plug-and-play capabilities to Haas vertical machining centres and turning centres

- Interfaces directly with the Haas control

- Single gripper included

- 50 kg capacity at wrist (part + gripper)

- Includes CE-compliant safety guard fencing.

- No need for additional M-code outputs, or the complex PLC connections used by 3rd-party integrators

HRP-3 Specifications

N.B. Specifications subject to change without notice.

| Axes | S.A.E | METRIC |

| Controlled Axes | 6 | 6 |

| Capacities | S.A.E | METRIC |

| Max Load Capacity at Wrist | 110.0 lb | 50 kg |

| Reach | 80.7 in | 2050 mm |

| Repeatability | 0.0010 in | 0.030 mm |

| Single Gripper | S.A.E | METRIC |

| Max Part Weight | 40.0 lb | 18.0 kg |

| Gripper Assembly Weight | 70.0 lb | 32.0 kg |

| Part Size - Round ø | 3.25 in to 2.10 in | 83 mm to 307 mm |

| Motion | S.A.E | METRIC |

| Motion Range – J1 | 360 ° | 360 ° |

| Motion Range - J2 | 225 ° | 225 ° |

| Motion Range - J3 | 440 ° | 440 ° |

| Motion Range - J4 | 720 ° | 720 ° |

| Motion Range - J5 | 250 ° | 250 ° |

| Motion Range - J6 | 720 ° | 720 ° |

| Speeds | S.A.E | METRIC |

| Max Speed - J1 | 175 °/sec | 175 °/sec |

| Max Speed - J2 | 175 °/sec | 175 °/sec |

| Max Speed - J3 | 175 °/sec | 175 °/sec |

| Max Speed - J4 | 250 °/sec | 250 °/sec |

| Max Speed - J5 | 250 °/sec | 250 °/sec |

| Max Speed - J6 | 355 °/sec | 355 °/sec |

| General | S.A.E | METRIC |

| Mounting Method | Floor Mount | Floor Mount |

| Weight | 1235 lb | 560.0 kg |

| Dimensions - Shipping | S.A.E | METRIC |

| Domestic Pallet | 106.5 in x 89.0 in x 80.0 in | 271 cm x 226 cm x 203 cm |

| Export Pallet | 106.5 in x 89.0 in x 80.0 in | 271 cm x 226 cm x 203 cm |

| Export Crate | 109.0 in x 92.0 in x 88.0 in | 277 cm x 234 cm x 224 cm |

| Weight | 3480 lb | 1580.0 kg |

| Domestic Crate for Safety Fence | 79.0 in 53.0 in 34.0 in | 201 cm 135 cm 86 cm |

| Export Crate for Safety Fence | 79.0 in 53.0 in 34.0 in | 201 cm 135 cm 86 cm |

| Weight for Safety Fence Crate | 1,200 lb | 544.0 kg |

- 1

- 2

- 3

- 4

SEE HAAS ROBOTS IN ACTION

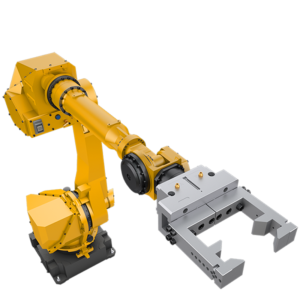

Easily Customise Your Haas Robot

When you get a Haas Robot Package you get a Plug & Play system that is ready to go out of the gate. Manufacturing Engineer Mallory Tevini gives us a bunch of great examples of ways you can make your robot cell fit your shop’s circumstances perfectly.

Haas Robotic Pallet Loader

Mike introduces Haas’ new Robotic Pallet Loader. This scalable and affordable Pallet Loading System includes the Haas 25 kg capacity robot, loading station, light curtain, pallet rack, and 3 zero point pallets. The RPL is plug-and-play compatible with Haas UMCs, and small and medium VMCs. All set up and operation are done through the Haas control and remote jog handle.

Fast Easy Automation

There’s never been an easier way to add a 6-axis robot to a Haas machine. With Haas Robot Packages, you set up and control the robot directly from the Haas control, with no need for complex PLC connections or a 3rd-party integrator.

Haas Robot Packages - Overview

Haas has three different Plug & Play Robot packages of varying sizes. In this video, we look at each of the three robot packages; what you get in the package, their capacity and reach, and the machines that each package will fit.

We’re here to answer all of your questions about adding a robot or cobot to your shop.

For details email us, or call 01603 760539.

quick reply form

Do you need funding?

Talk to our dedicated team

Haas Financial Services can find you the most competitive funding options from our extensive portfolio of funders.

Navigating your way through the different forms of lending banks and companies have to offer can be hard.

Get in touch and we’ll be able to help you find the perfect option to finance your business and let you take the next step.

For more details on finance packages, please call 01603 227838 or email: finance@haas.co.uk