Desktop Lathe

63 mm

Chuck Size

3K rpm

Spindle

220 V

Single Phase

1.5 hp

Power

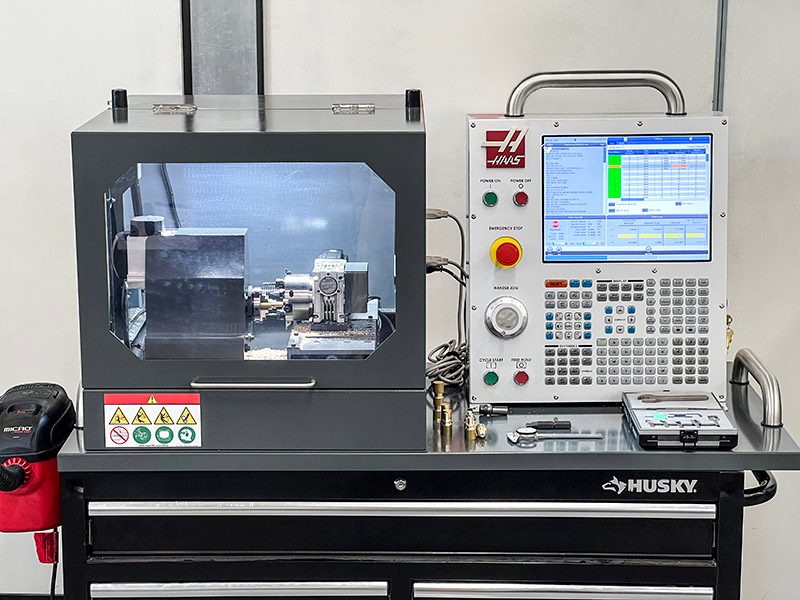

The Haas Desktop Lathe is the ultimate training machine for schools and technical colleges. Powered by a full-function Haas CNC control housed in our portable simulator enclosure, the Desktop Lathe is perfect for teaching the basic principles of programming and operating a CNC lathe. Designed to cut brass, plastics, and machinable wax, it is also perfect for hobbyists and benchtop machinists.

NOTE: Includes 3 wedge clamps and 1 anti-rotation pin. Complete tooling kit available.

- Portable design easily fits onto a desktop or rolling toolbox

- Powered by a full-function Haas control

- Ethernet and WiFi connectivity

- M130 Media Display M-code

Desktop Lathe Specifications

N.B. Specifications subject to change without notice.

| CAPACITIES | S.A.E | METRIC |

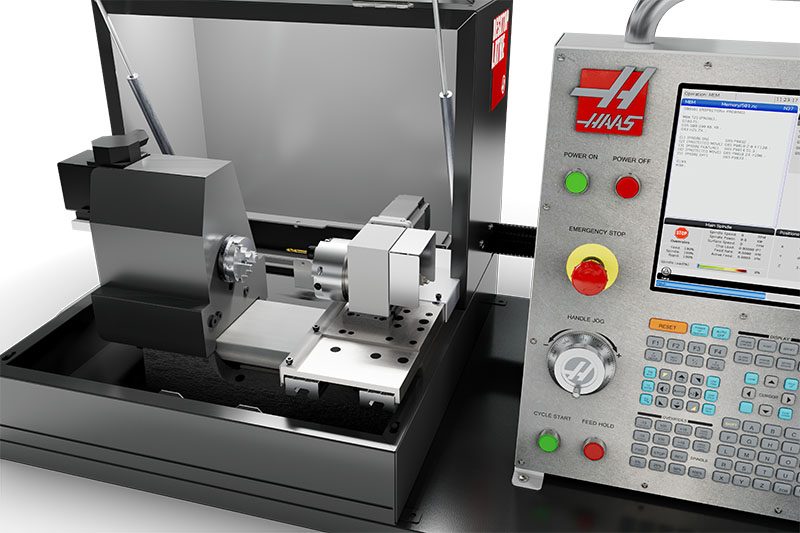

| Chuck Size | 2.5 in | 63 mm |

| Max Cutting Diameter | 0.75 in | 19 mm |

| TRAVELS | S.A.E | METRIC |

| X Axis | 2.70 in | 69 mm |

| Z Axis | 2.75 in | 70 mm |

| SPINDLE | S.A.E | METRIC |

| Max Rating | 1.5 hp | 1.1 kW |

| Max Speed | 3000 rpm | 3000 rpm |

| TURRET | S.A.E | METRIC |

| Number of Tools | 6 Stations | 6 Stations |

| OD vs ID Tools | 3 OD (6x6x8 mm) / 3 ID (16 mm ) | 3 OD (6x6x8 mm) / 3 ID (16 mm ) |

| GENERAL | S.A.E | METRIC |

| Machine Weight | 265 lb | 120 kg |

| ELECTRICAL SPECIFICATION | S.A.E | METRIC |

| Power Requirement | 110 VAC | 220 VAC @ 20 A | 110 VAC | 220 VAC @ 20 A |

| DIMENSIONS - SHIPPING | S.A.E | METRIC |

| Export Crate | 56.0 in x 37.0 in x 35.0 in | 142 cm x 94 cm x 89 cm |

| Weight | 360 lb | 164.0 kg |

- 1

- 2

DESKTOP LATHE CUTTING DEMO

Desktop Mill - Sneak Peak

The Haas Desktop Lathe is the ultimate training machine for schools and technical colleges, and perfect for teaching the basic principles of programming and operating a CNC lathe

Desktop Mill Walk-Through

Powered by a full-function Haas CNC control, the Desktop Lathe is perfect for teaching the basic principles of programming and operating a CNC lathe.

Designed to cut brass, plastics, and machinable wax, it is also perfect for hobbyists and benchtop machinists.

WHAT IS G-CODE?

In the latest Tip of the Day episode, Mark answers a question we get asked all the time: “What is G-Code?” Not only will you get a quick history of G-Code, going back to its beginnings in the 1950s, but Mark also explains how G-Code is used today on modern Haas CNC machines.

DISPLAY PICTURES AND VIDEOS ON YOUR HAAS CONTROL USING M130

With M130, you can display setup sheets, tool lists, work instructions, and even videos – all within your program. No more taping work instructions to the machine, or hand writing notes telling your operator how to load or inspect a part; put it all in your CNC program!

We’re here to answer all of your questions about adding a Desktop Mill or Desktop Lathe to your classroom or workshop.

For details email us, or call 01603 760539.

quick reply form

Do you need funding?

Talk to our dedicated team

Haas Financial Services can find you the most competitive funding options from our extensive portfolio of funders.

Navigating your way through the different forms of lending banks and companies have to offer can be hard.

Get in touch and we’ll be able to help you find the perfect option to finance your business and let you take the next step.

For more details on finance packages, please call 01603 227838 or email: finance@haas.co.uk