The ALL NEW Super Mini Mill

Mini in Name.

Mighty in Performance.

Machine performance was once paired with size and cost. The Haas Super Mini Mill changed everything by packing 40-taper performance into a small package at unheard-of prices.

And now, we’re delivering even more value than ever before with increased travel, higher speeds, and more features.

Haas Mini Mills are the industry standard for compact machining centres. They are perfect for schools, start-up shops, or as a first step into CNC machining. Loaded with full-size features, they are valuable additions for shops needing a “second-op” machine or an additional spindle where space is limited.

Our Super Mini Mill Series machines are fully capable vertical mills, with many of the same components and options from our VF Series – but with smaller footprints.

You don’t need a huge space to make the most of your manufacturing capabilities. CNC machining doesn’t have to happen in a huge warehouse. Haas has proven that for more than 30 years.

Big upgrades, same compact footprint

We offer a wide selection of compact, affordable, easy-to-use CNC machines to fit any shop size or budget, whether you’re a start-up shop, taking your first step into CNC machining, or looking to bring your machining in-house.

FEA optimised castings

REDESIGNED to increase the overall rigidity and stability of the machine. The new castings are 30% heavier, but we only added material where needed, to increase performance without increasing cost.

Y-Axis washdown

The ALL-NEW Y-axis washdown nozzle flushes chips from the rear Y-axis waycover to prevent chip build-up behind the table during extended machining operations.

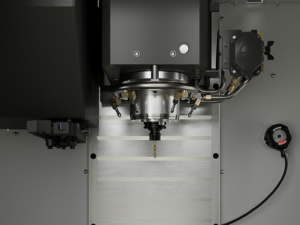

Side mount tool changer

NOW STANDARD on the Super Mini Mill, this Haas designed and built 30+1 side-mount tool changer provides more tools and faster tool changes, while freeing up the work envelope for larger fixtures and rotary tables.

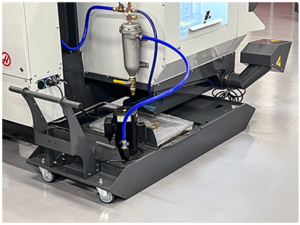

External coolant tank

NOW STANDARD on all Mini Mills, the 45-gallon (170-litre) external coolant tank simplifies coolant maintenance and tank cleanout and provides additional coolant capacity.

Faster spindles and rapids

NOW STANDARD on the Mini Mill, our 8,000-rpm grease-packed spindle provides more rpm than the previous models, allowing higher feedrates and yielding more horsepower and torque for heavier cuts.

Side windows

Side windows are NOW STANDARD on all Mini Mills, providing additional access for job set-up and cleaning, as well as better visibility during machining. An available auto window makes it easy to add a Haas Cobot or APL for easy automation.