Ginetta Cars

Life in the Fast Lane

Founded in 1958 by the four Walklett brothers, Ginetta has a long and successful history of producing hand-built road and race cars. By the time it was acquired by Lawrence Tomlinson’s LNT Group in 2005, it had gained a reputation as one the most renowned British heritage race car brands. Taking the lead in British race car manufacturing, Ginetta is putting the UK at the heart of world-class motorsport, selling cars across the world and training the brightest stars in motor racing.

Ginetta offers a genuine route for progression from entry level competition, right the way through to international motorsport platforms. Occasional race enthusiasts can choose to hire a car or host a corporate day, while the more seasoned racing driver can experience driver training on an advanced track day.

The Ginetta Championships provide competitive racing for everyone, from the Ginetta Junior Championship – with drivers aged 14-17 – racing the multi-disciplined G40, to the Michelin Ginetta GT4 SuperCup. Broadcast live on ITV4, it is a stepping stone into a career in professional motorsport.

Every car is hand-built in a state-of-the-art, 75,000 ft2 factory just outside Leeds in West Yorkshire. Ginetta employs some of the UK’s sharpest engineering and manufacturing talent to take each model from concept to reality, combining thorough engineering and quality control with the ability to move rapidly from prototype to production.

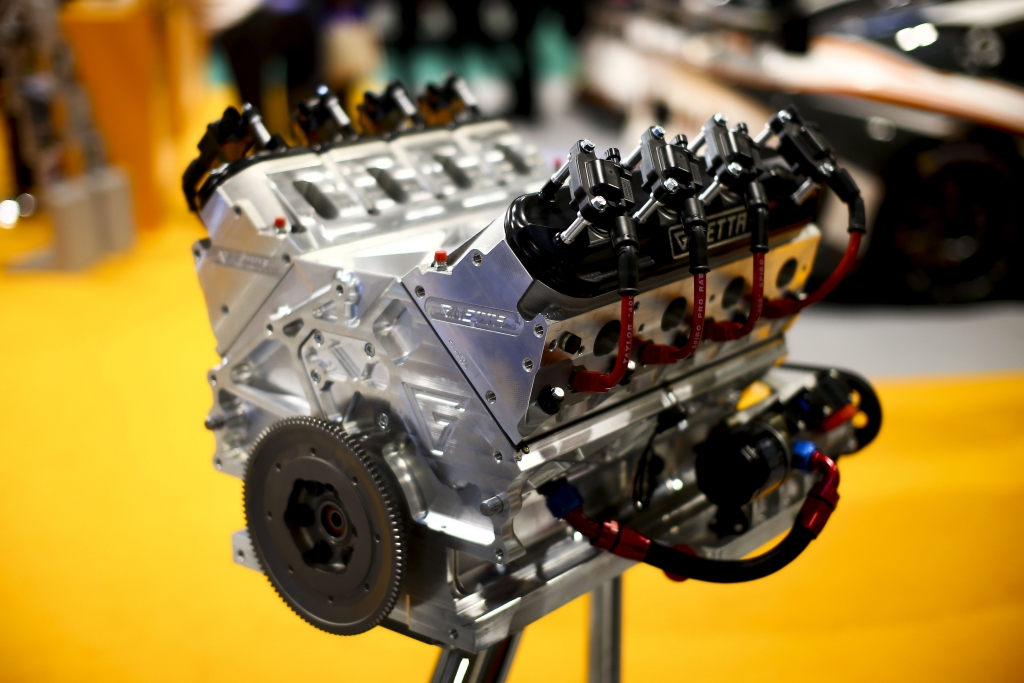

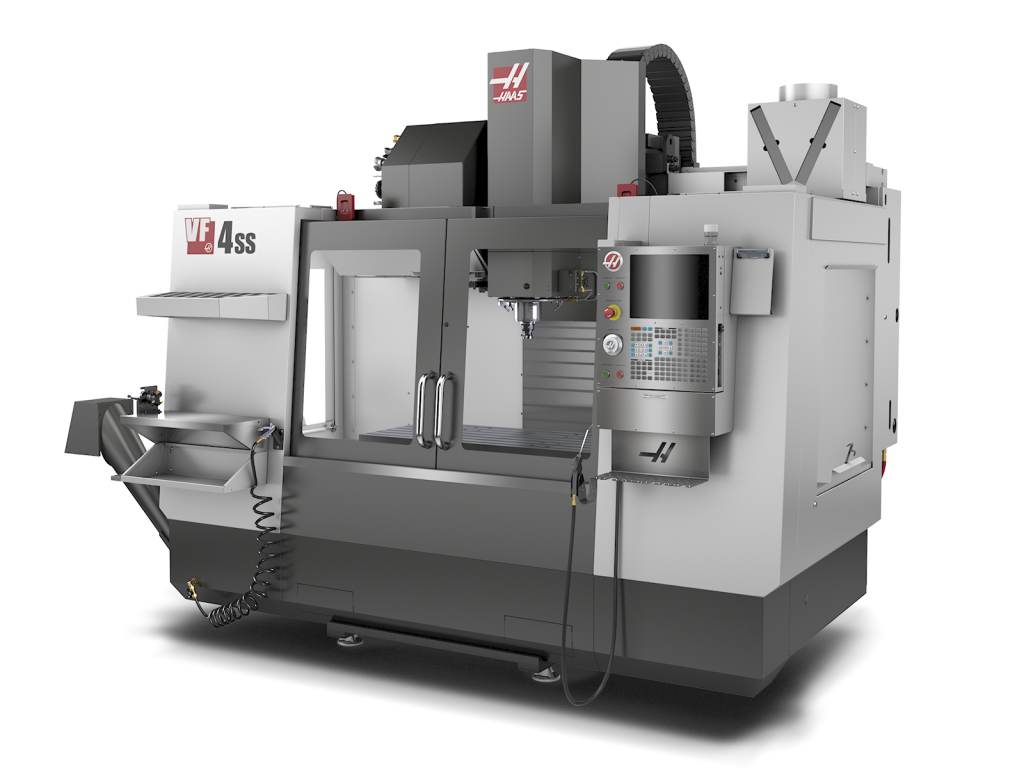

In 2016 Ginetta invested in their first CNC machine tool; a Haas VF-4SS Super Speed vertical mill with 12,000 RPM spindle, 24+1 tool stations and 4 axis control. The machine is central to the manufacture of the new G58 – an evolution of the popular G57. This latest prototype was created in response to feedback from existing customers and will boast a 6.2 litre V8 engine, capable of producing 575 BHP. Tipped to be one of the fastest track day machines on the market, the G58 will lap within four seconds of an LMP2 car, at a fraction of the cost.

The VF-4SS is also cutting parts for the new G60-LT-P1, recently unveiled at Autosport 2018, which is bound for the 2018/19 FIA world Endurance Championships, including Le Mans 24 Hours.

Daniel Shaw, Supply Chain Manager explains why they chose Haas; “The Super Speed Haas is perfect for machining the highly complex aluminium parts we produce. It’s very easy to use and great value for money. The complete package was so good we couldn’t say no.”

The last few years have seen unprecedented success, with company turnover increasing by nearly 50%. Investing in Haas, as well as in research and development, alongside further improvements to the range have led to growing demand from international markets.

“The Super Speed Haas is perfect for machining the highly complex aluminium parts we produce. It’s very easy to use and great value for money. The complete package was so good we couldn’t say no.”

Daniel Shaw, Supply Chain Manager