Haas offers many different options for automating your shop, from Automatic Part Loaders and Pallet Pools, to fully integrated Robot Systems. Depending on your shop’s needs, there’s an automation system that’s right for you.

Haas makes AUTOMATION Easy

✓ Fully integrated, plug-and-play Robot Packages

✓ Machine + Robot + Integration + Single Control + Haas Service

IT’S NEVER BEEN EASIER OR MADE MORE SENSE TO GET AUTOMATED

Labour shortages, optimising productivity, and increasing efficiency are just some of the reasons to automate your production. From big to small, every shop should be investing in automation. It’s easier (and more affordable) than you think.

WHICH AUTOMATION SYSTEM IS RIGHT FOR YOU?

Robots

There’s never been an easier way to add a 6-axis robot to a Haas machine. With Haas Robot Packages, you set up and control the robot directly from the Haas control, with no need for complex PLC connections or a 3rd-party integrator.

Haas Robot Packages are the easiest and quickest to set up in the industry, and you don’t need a 3rd-party integrator. The Haas Engineering Department will do the install for you in just a few hours, rather than the days or weeks required for other systems.

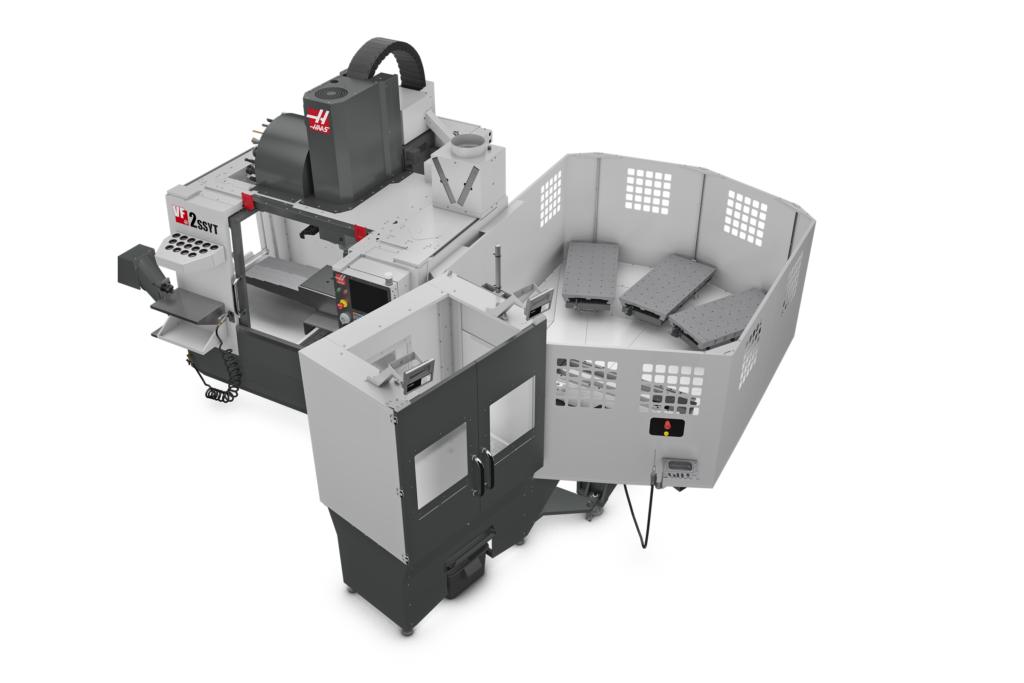

Pallet Pools

Whether you’re doing high-volume production runs, high-mix/low-volume machining, or just want to run lights-out, our fully integrated pallet pool systems can boost your productivity.

The Haas Pallet Pools integrate seamlessly with the Haas control, which includes a simplified Pallet Schedule Table that allows pallet-scheduling functions from a single dedicated screen.

Auto Parts Loaders

The Auto Parts Loaders (APL)provide simple and affordable automation on haas turning centres and mills. The APLs integrate seamlessly with the Haas control, and are set up through a simple, intuitive interface that uses graphics, animations, and detailed text to guide the operator.

Simply enter basic information by either positioning the part grippers and pushing a single button, or by entering basic numeric values. All values are calculated automatically by the control, and the APL is ready to go.

AUTOMATION OPTIONS AND CONFIGURATIONS CHART

We’re here to answer all of your concerns about adding a robot to your shop.

It doesn’t actually take up that much space, cost a ton of money, or take weeks to integrate.

Watch the videos below to learn more.

Space Efficient

Cost Effective

Easy to Integrate

Easy to Learn

DO YOU NEED FUNDING?

TALK TO OUR DEDICATED TEAM

Haas Financial Services can find you the most competitive rates from our extensive portfolio of funders.

Call Simon or Tim on 01603 227838.