Desktop Mill

ER-11 Collet

Taper

15K rpm

Spindle

220 V

Single Phase

3

AXIS

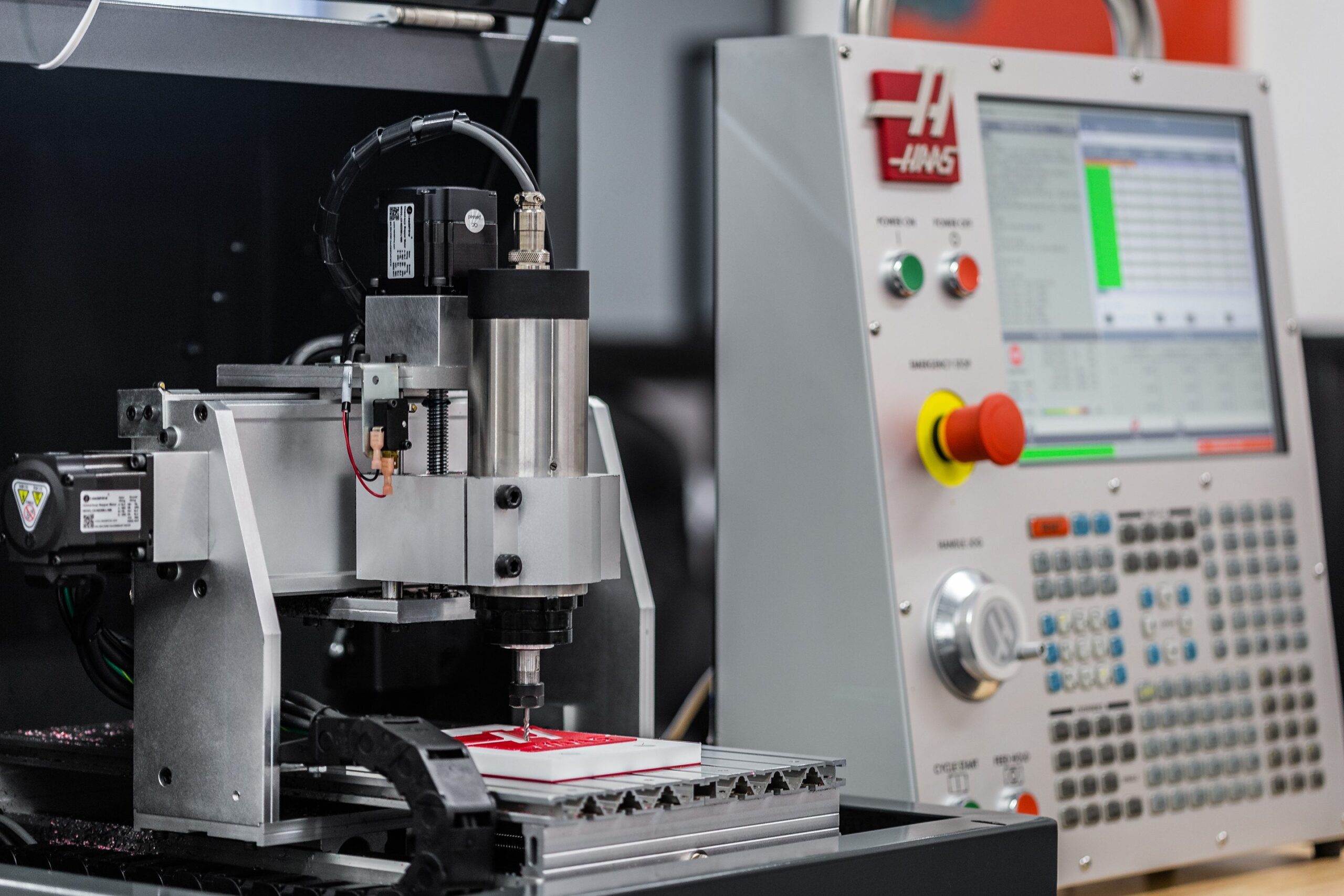

The Haas Desktop Mill is the ultimate training machine for schools and technical colleges. Powered by a full-function Haas CNC control housed in our portable simulator enclosure, the Desktop Mill is perfect for teaching the basic principles of programming and operating a CNC mill. Designed to cut plastics and machinable wax, it is also perfect for hobbyists and benchtop machinists.

CNC Pen Holder: Converts the Desktop Mill into a CNC plotter, for drawing, proofing toolpaths, and teaching CNC programming.

Available software package: High-Speed Machining, Haas Visual Programming System, User-Definable Macros, and Coordinate Rotation & Scaling.

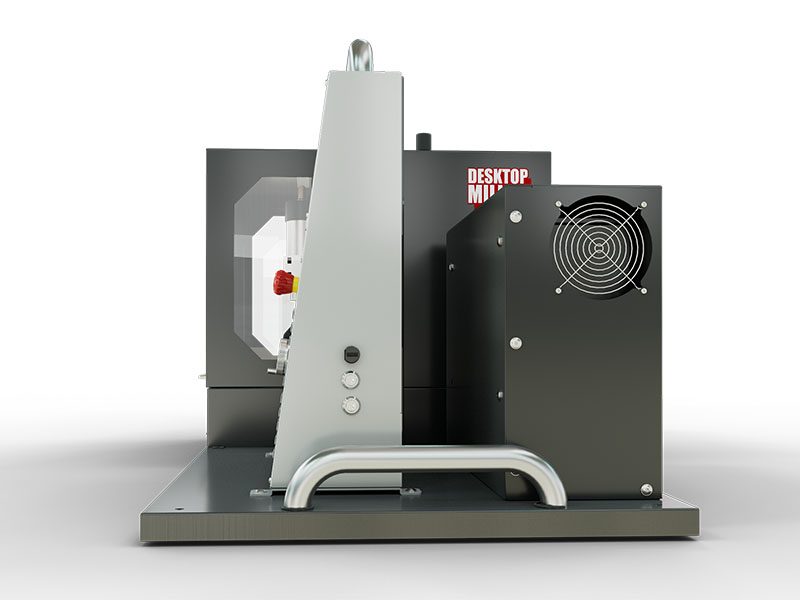

- Portable design easily fits onto a desktop or rolling toolbox

- Powered by a full-function Haas control

- 15,000-rpm electric spindle

- Ethernet and WiFi connectivity

- M130 Media Display M-code

NOTE: Running the spindle slower than 1500 rpm can cause the spindle to overheat.

Desktop Mill Specifications

N.B. Specifications subject to change without notice.

| TRAVELS | S.A.E | METRIC |

| X Axis | 6.00 in | 152 mm |

| Y Axis | 10.00 in | 254 mm |

| Z Axis | 3.00 in | 76 mm |

| Spindle Nose to Table (~ max) | 3.2 in | 80 mm |

| SPINDLE | S.A.E | METRIC |

| Max Speed | 15000 rpm | 15000 rpm |

| Drive System | Integral Spindle/Motor | Integral Spindle/Motor |

| Taper | ER11 Collet | ER11 Collet |

| TABLE | S.A.E | METRIC |

| Length | 18.1 in | 460 mm |

| Width | 10.6 in | 270 mm |

| T-Slot Width | 0.390 in | 10 mm |

| T-Slot Center Distance | 1.77 in | 45 mm |

| Number of Std T-Slots | 6 | 6 |

| FEEDRATES | S.A.E | METRIC |

| Max Cutting | 140 ipm | 3.6 m/min |

| Rapids on X | 140 ipm | 3.6 m/min |

| Rapids on Y | 140 ipm | 3.6 m/min |

| Rapids on Z | 140 ipm | 3.6 m/min |

| ELECTRICAL SPECIFICATION | S.A.E | METRIC |

| Input AC Voltage (1 Phase) | 220 VAC | 220 VAC |

| Full Load Amps (1 Phase) | 15 A | 15 A |

- 1

- 2

SEE THE DESKTOP MILL IN ACTION

Desktop Mill - Sneak Peak

The Haas Desktop Mill is a portable CNC machine geared toward the education and hobbyist market. It is perfect for learning the fundamentals of CNC programming, right on the industry-leading Haas control. Operate and program a fully functioning Haas CNC machine, right on your desktop.

Desktop Mill Walk-Through

Aimed at the education sector, as well as the benchtop machinist, the Desktop Mill combines a full-featured Haas control with a desktop-sized machine to create the perfect package for both teaching and learning the basics of CNC programming and operation.

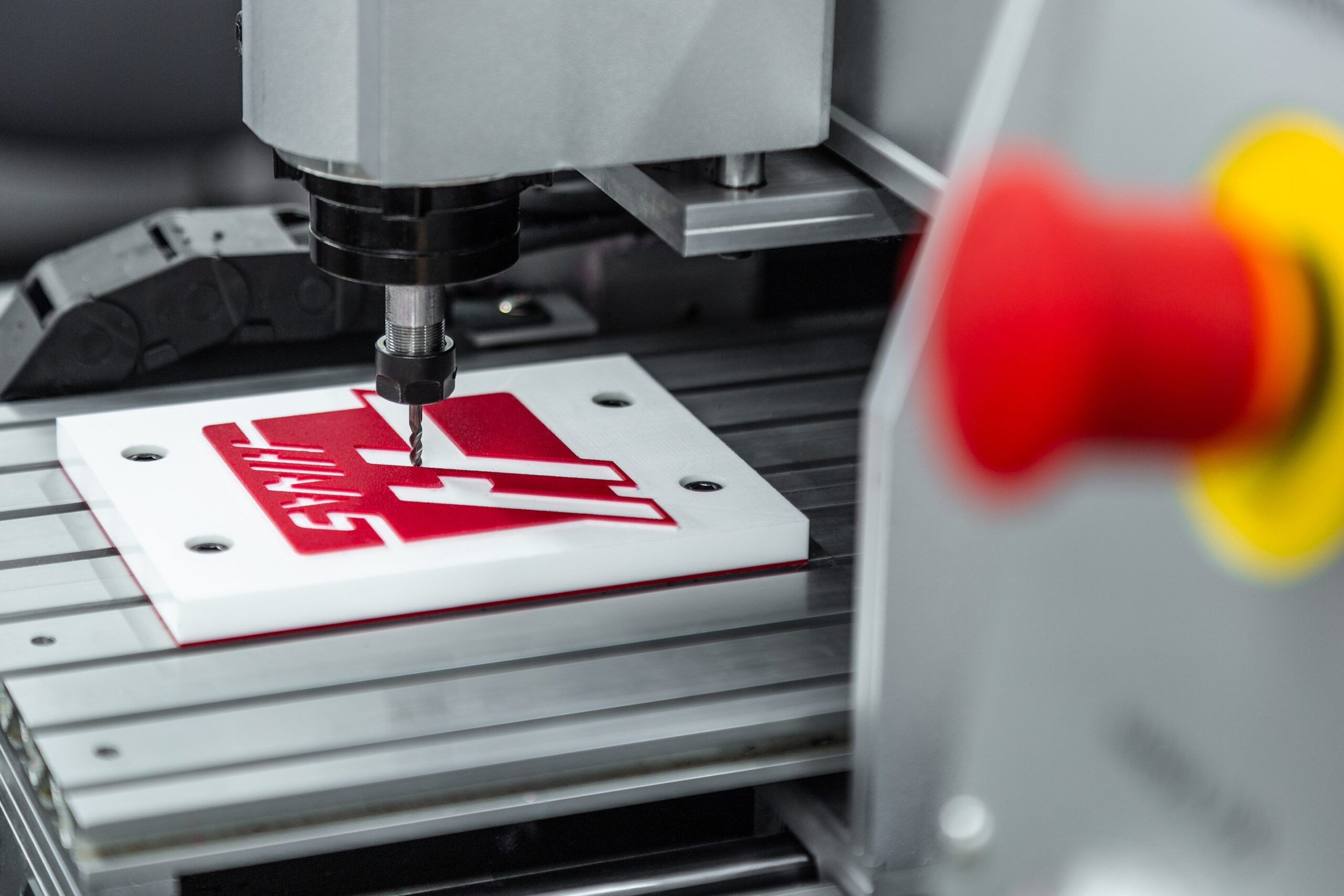

Desktop Mill Cutting Demo

The Desktop Mill is perfect for teaching the basic principles of programming and operating a CNC mill.

Designed to cut plastics and machinable wax, it is also perfect for hobbyists and benchtop machinists.

DISPLAY PICTURES AND VIDEOS ON YOUR HAAS CONTROL USING M130

With M130, you can display setup sheets, tool lists, work instructions, and even videos – all within your program. No more taping work instructions to the machine, or hand writing notes telling your operator how to load or inspect a part; put it all in your CNC program!

We’re here to answer all of your questions about adding a Desktop Mill or Desktop Lathe to your classroom or workshop.

For details email us, or call 01603 760539.

quick reply form

Do you need funding?

Talk to our dedicated team

Haas Financial Services can find you the most competitive funding options from our extensive portfolio of funders.

Navigating your way through the different forms of lending banks and companies have to offer can be hard.

Get in touch and we’ll be able to help you find the perfect option to finance your business and let you take the next step.

For more details on finance packages, please call 01603 227838 or email: finance@haas.co.uk