Demo Days

CAD to Cut

Wednesday 14th May

Thursday 15th May

Join Haas Automation for a Special Event featuring our partners Autodesk and MA Ford.

Discover the seamless connection between Haas CNC machines, Autodesk’s Fusion software, and the latest tooling innovations from MA Ford. See how this powerful trio can enhance your productivity, boost efficiency, and help you get more from every cycle.

Enjoy live demonstrations, expert insights, and a chance to see how everything works together for your CNC workshop.

What’s more, all attendees will have the chance to win Grandstand Tickets to the 2025 British F1 Grand Prix in July.

- 10am – 8pm Wednesday 14th May

- 10am – 5pm Thursday 15th May

- 10am – 8pm Wednesday 14th May

Please call 01603 760539 or email sales@haas.co.uk for more details.

WIN F1 Tickets to the 2025 British F1 Grand Prix at Silverstone!

Three lucky event attendees will each win a pair of Grandstand Tickets to the 2025 British Grand Prix at Silverstone.

1st Prize: Two Grandstand Tickets for Race Day – Sunday 6th July

2nd Prize: Two Grandstand Tickets for Qualifying – Saturday 5th July

3rd Prize: Two Grandstand Tickets for Practice Session – Friday 4th July

*T&Cs apply – see here

Book your visiting time

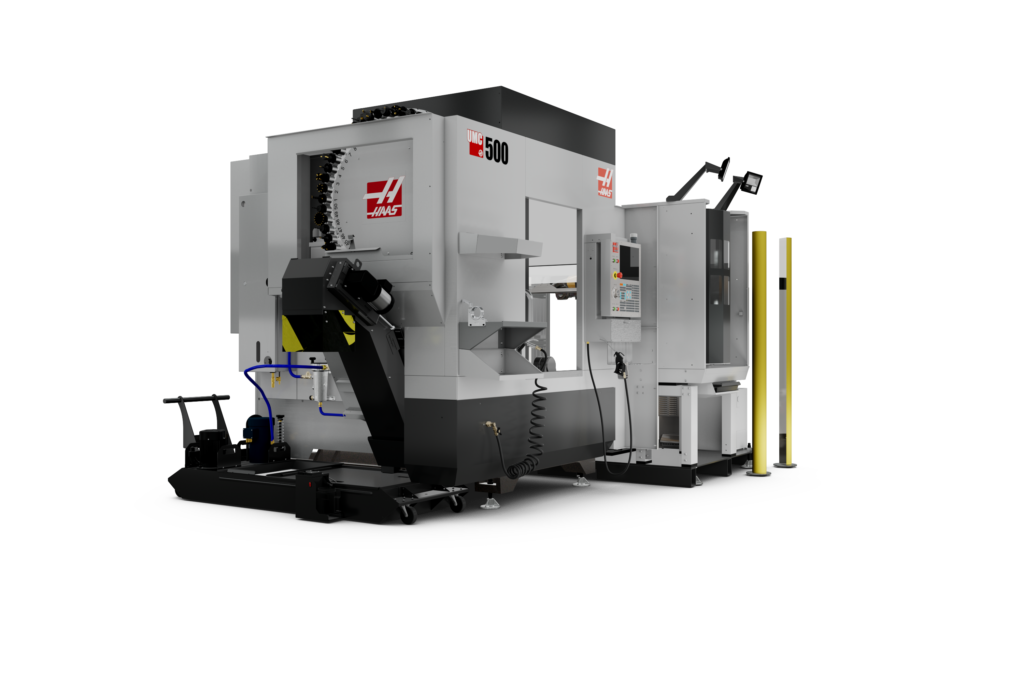

Robot pallet loader + UMC-500

SCALABLE, AFFORDABLE PALLET LOADING SYSTEM

Available on these models (and Super Speed versions):

- UMC-500/UMC-750/UMC-1000/UMC-1250

- VF-2/VF-3/VF-4/VF-5

INCLUDES the Haas 25 kg capacity robot, loading station, light curtain, pallet rack, and 3 zero point pallets (expandable to 15 pallets).

SUper mini mill + Auto parts loader

The best value compact parts loader system available

Autodesk fusion

Design and manufacturing solutions for everyone

Autodesk Fusion works seamlessly with Haas CNC machines, making it easy to go from design to production in one smooth workflow. With built-in CAM tools and Haas-specific post processors, it reduces setup time, minimises errors, and boosts efficiency. See it in action at the event – watch how this powerful combination streamlines programming, enhances precision, and speeds up production.

UMC-500

5-AXIS UNIVERSAL MACHINE

The UMC-500 has the capability of the UMC-750 together with the design improvements of the UMC-1000. Furthermore, it sits on a footprint just slightly larger than a VF-2.

MA FORD TOOLING

The cutting edge of tooling design and manufacture

MA Ford’s latest tooling innovations – like the XV5CB end mills with ALtima® Q coating and the new FHFP high-feed cutters – are designed for speed, precision, and long-lasting performance across tough materials. With advanced geometries that reduce vibration and cutting forces, they’re ideal for high-efficiency machining. See the latest advances in action on a Haas CNC at the event and discover how MA Ford tooling can take your productivity to the next level.

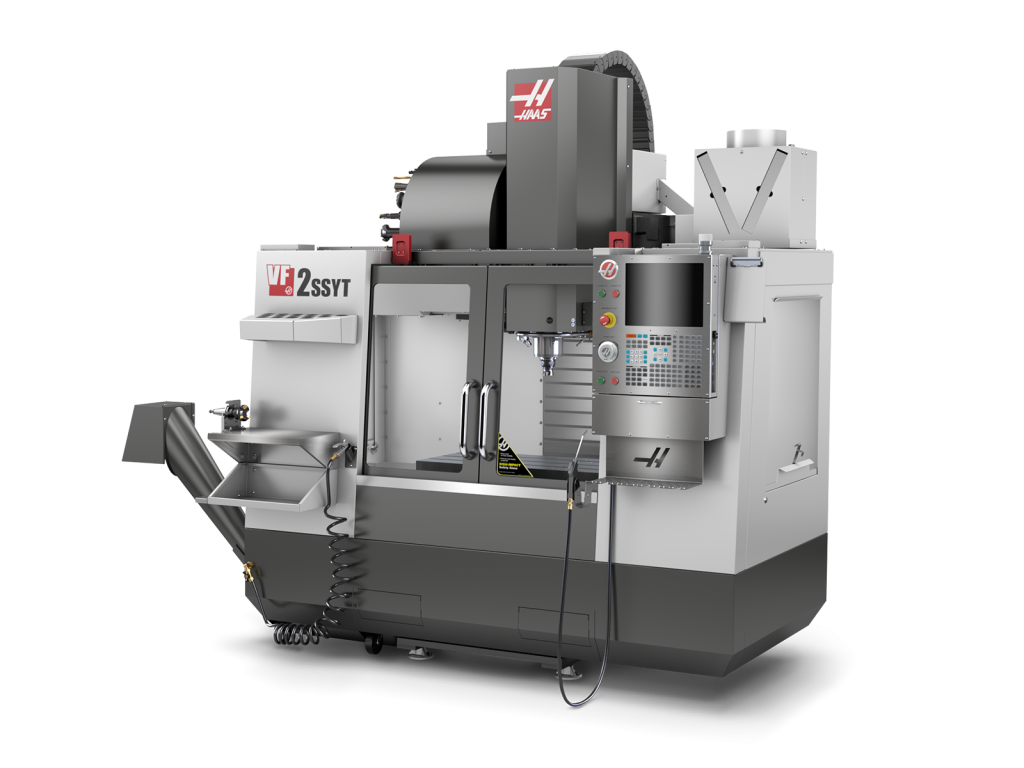

VF-2SSYT

Super Speed VMC

The Haas high-performance Super-Speed vertical machining centres provide the high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production and reduced cycle times. Each SS machine features a 12,000-rpm, inline direct-drive spindle, an ultra-fast side-mount tool changer, and high-speed rapids on all axes.

The VF-2SSYT offers more Y-axis travel than our very popular VF-2SS.

DS-30Y

Y-AXIS DUAL SPINDLE TURNING CENTRE

The DS-30Y Y-axis Dual-Spindle CNC Lathe combines dual-spindle turning with Y-axis, C-axis, and live tooling to create a powerful “done-in-one” machining solution for any shop. Off-centre milling, drilling, and tapping operations are possible for increased machining capabilities. It comes standard with a 12-station BMT65 turret and synchronized C-axis for versatile 4-axis capability.

Pre-owned haas cnc machines

Take a tour of our new Pre-Owned Machines Workshop. See how we get our pre-owned machines in the best shape of all used Haas machines in the industry.

We have a selection of pre-owned and ex-demo Haas CNC machines. These Haas machines will be in excellent condition and have been checked and serviced by our Engineering Department.

FIND US HERE:

Haas Automation Ltd

Wymondham Business Park,

12 Chestnut Drive,

Wymondham

NR18 9SB

Do you need funding?

Talk to our dedicated team

Haas Financial Services can find you the most competitive funding options from our extensive portfolio of funders.

Navigating your way through the different forms of lending banks and companies have to offer can be hard.

Get in touch and we’ll be able to help you find the perfect option to finance your business and let you take the next step.

For more details on finance packages, please call 01603 227838 or email: finance@haas.co.uk

Terms and Conditions – Haas F1 Tickets Prize Draw

- This prize draw is open to all attendees of the Haas CAD to Cut Open Day: 14th & 15th May.

- Three winners will be selected at random from the list of registered attendees.

- Prizes are as follows:

- 1st Prize: Pair of Grandstand Tickets for Race Day – Sunday at the British F1 Grand Prix, Silverstone.

- 2nd Prize: Pair of Grandstand Tickets for Saturday at the British F1 Grand Prix, Silverstone.

- 3rd Prize: Pair of Grandstand Tickets for Friday at the British F1 Grand Prix, Silverstone.

- Tickets are non-transferable and cannot be exchanged for cash or any alternative.

- Winners will be notified by email or telephone shortly after the draw.

- If any winner cannot be contacted within seven days of notification, Haas reserves the right to select another winner.

- By entering the prize draw, participants agree to these terms and conditions.

- Haas reserves the right to amend or withdraw this promotion at any time.

- Entry solely for registered attendees; employees and representatives of Haas Automation, Autodesk and MA Ford are not eligiblibe for entry.

These terms and conditions are governed by UK law.