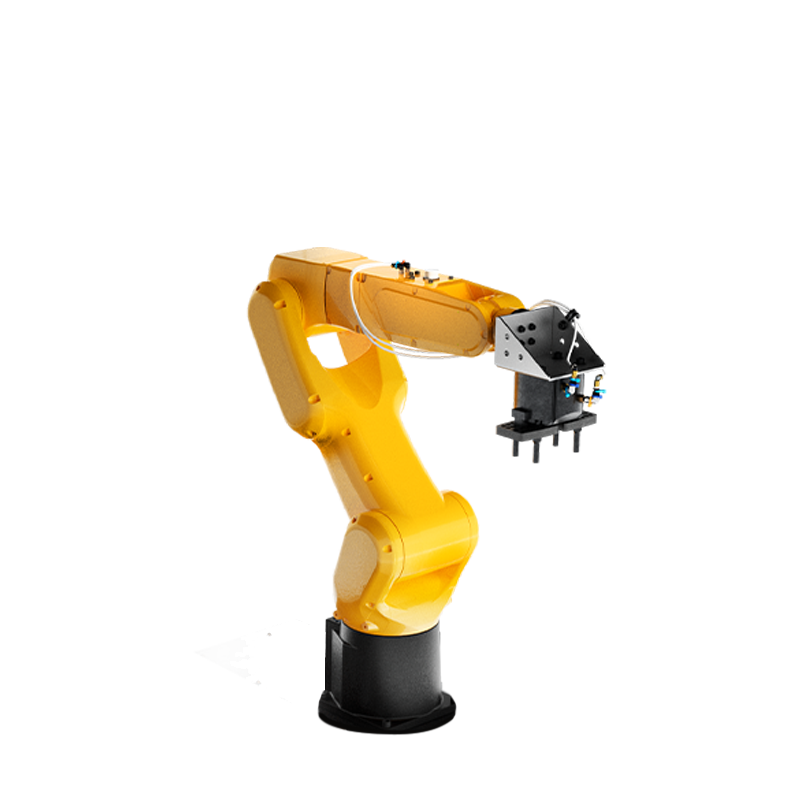

HC-10 Cobot

10 kg

Capacity

157 mm

Max Part Dia.

1000 mm

Reach

6

AXIS

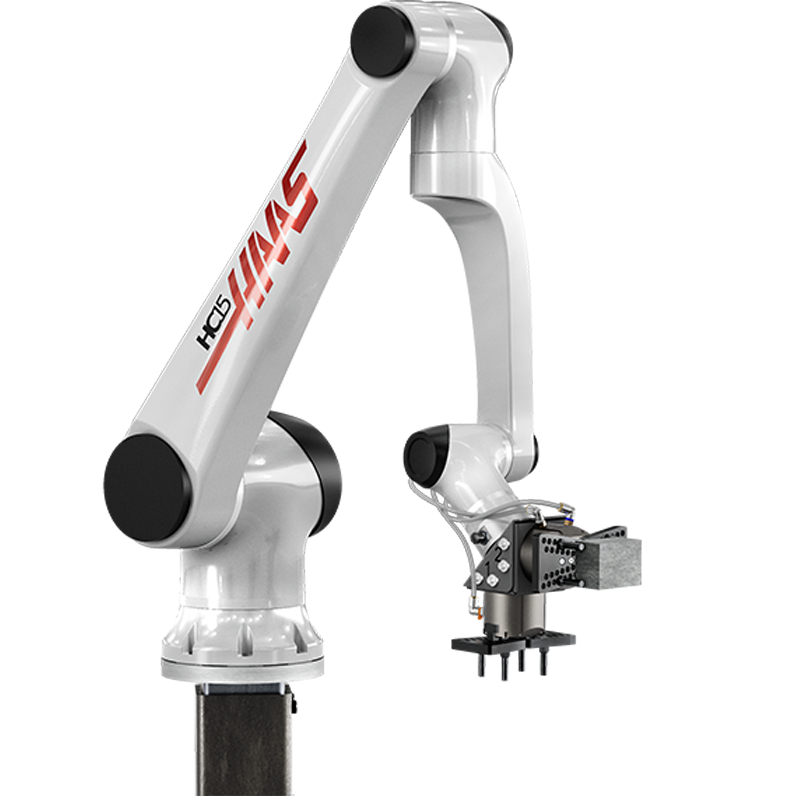

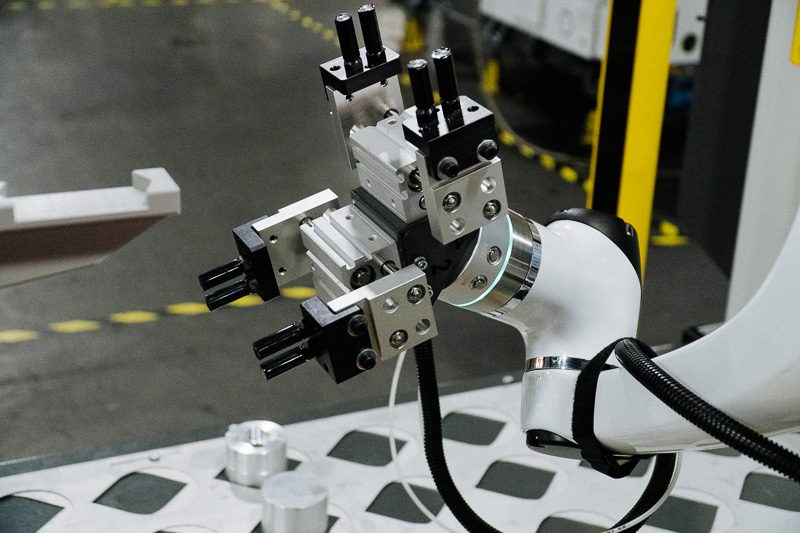

All-in-one cobot kit for your new machine! The Haas 10 kg Cobot Package includes everything required to run your new cobot directly from the Haas control. This kit features the HC10 Cobot with a 10 kg capacity, dual pneumatic grippers, protective barriers, a temporary mounting base*, a parts table, a part flip station, and all necessary hardware and cables.

10 KG CAPACITY | 1000 MM REACH

AVAILABLE ON: Small VFs, ST-10 through ST-28, DTs, DMs, DC-1, DC-2, Mini Mills, UMC-400/SS, and UMC-500/SS

*Does not ship pre-built. The temporary mounting base is for optional use, and is not included in Europe. Floor mounting is recommended. Cobot carries a one-year warranty.

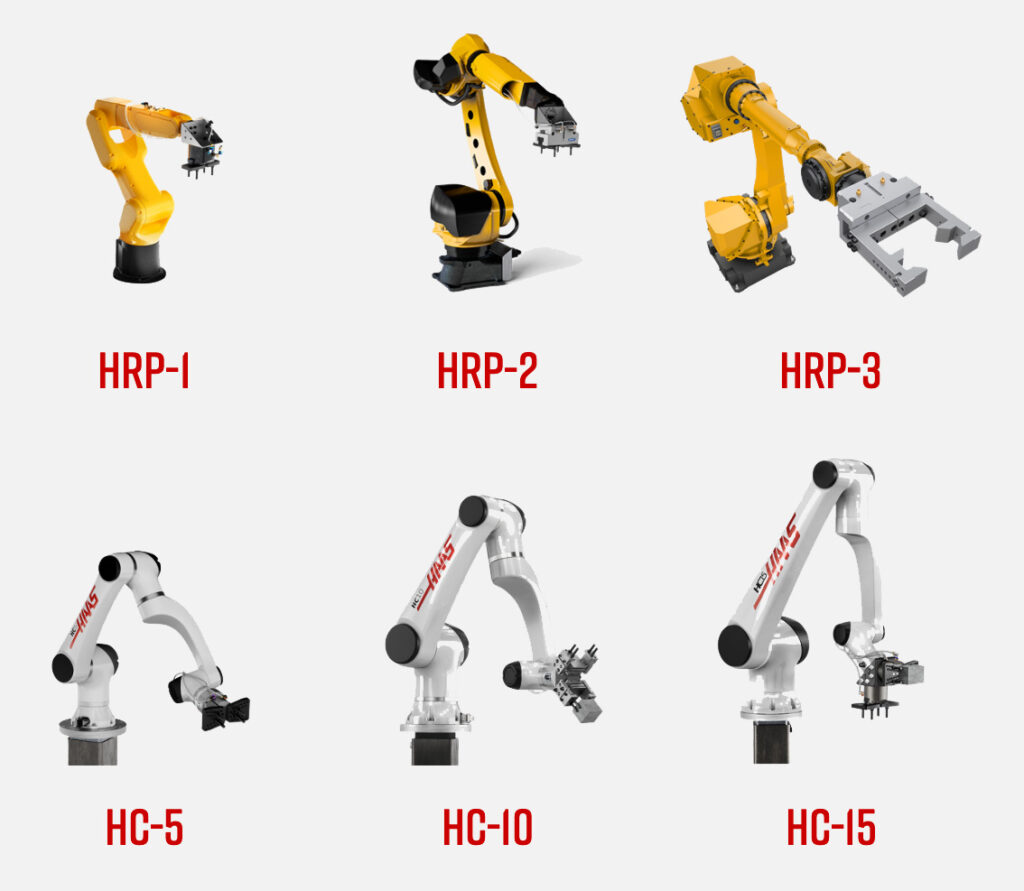

ROBOT & COBOT PACKAGES

HC-10 Specifications

N.B. Specifications subject to change without notice.

| Axes | S.A.E | METRIC |

| Controlled Axes | 6 | 6 |

| Capacities | S.A.E | METRIC |

| Max Load Capacity at Wrist | 22.0 lb | 10 kg |

| Reach | 39.0 in | 1000 mm |

| Repeatability | 0.0012 in | 0.030 mm |

| Single Gripper | S.A.E | METRIC |

| Max Part Weight | 14.5 lb | 6.6 kg |

| Gripper Assembly Weight | 7.5 lb | 3.4 kg |

| Part Size - Round ø | 0.63 in to 6.20 in | 16 mm to 157 mm |

| Part Width - Rectangular | 0.38 in to 6.00 in | 10 mm to 152 mm |

| Part Length - Rectangular | 0.90 in to 2.20 in | 23 mm to 56 mm |

| Dual Gripper | S.A.E | METRIC |

| Max Part Weight (per gripper) | 2.5 lb | 1.1 kg |

| Gripper Assembly Weight | 7.0 lb | 3.2 kg |

| Part Size - Round ø | 1.00 in to 6.00 in | 25 mm to 52 mm |

| Part Width - Rectangular | 0.75 in to 6.25 in | 19 mm to 159 mm |

| Part Length - Rectangular | 0.90 in to 1.65 in | 23 mm to 42 mm |

| Motion | S.A.E | METRIC |

| Motion Range – J1 | 720 ° | 720 ° |

| Motion Range - J2 | 270 ° | 270 ° |

| Motion Range - J3 | 306 ° | 306 ° |

| Motion Range - J4 | 720 ° | 720 ° |

| Motion Range - J5 | 360 ° | 360 ° |

| Motion Range - J6 | 720 ° | 720 ° |

| Speeds | S.A.E | METRIC |

| Max Speed - J1 | 100 °/sec | 100 °/sec |

| Max Speed - J2 | 100 °/sec | 100 °/sec |

| Max Speed - J3 | 150 °/sec | 150 °/sec |

| Max Speed - J4 | 150 °/sec | 150 °/sec |

| Max Speed - J5 | 180 °/sec | 180 °/sec |

| Max Speed - J6 | 180 °/sec | 180 °/sec |

| General | S.A.E | METRIC |

| Mounting Method | Pedestal Mount | Pedestal Mount |

| Wrist Flange Mounting Type | ISO 9409-1-50-4M6 | ISO 9409-1-50-4M6 |

- 1

- 2

- 3

SEE HAAS COBOTS IN ACTION

Haas Robot Packages - Overview

Alex walks us through programming a complete part setup on the Haas HC10 Cobot. The Haas HC10 is a fully integrated, plug-and-play, 10kg capacity collaborative robot for Haas machines.

Haas Cobots - Choosing the Right Platform

Mike introduces Haas’ new Cobot Kit! You get absolutely amazing value when you purchase this kit along with a new machine. The Haas all-in-one Machine Ready Cobot kit includes everything required to run your new Cobot right off the Haas control.

Fast Easy Automation

There’s never been an easier way to add a 6-axis robot to a Haas machine. With Haas Robot Packages, you set up and control the robot directly from the Haas control, with no need for complex PLC connections or a 3rd-party integrator.

Automated Machining Cell VS Manually Loaded

Check out this animated infographic that shows the potential output increase and labor hours decrease when switching to an automated cobot loaded cell from a manually loaded machining cell.

We’re here to answer all of your questions about adding a Robot or Cobot to your shop.

For details email us, or call 01603 760539.

quick reply form

Do you need funding?

Talk to our dedicated team

Haas Financial Services can find you the most competitive funding options from our extensive portfolio of funders.

Navigating your way through the different forms of lending banks and companies have to offer can be hard.

Get in touch and we’ll be able to help you find the perfect option to finance your business and let you take the next step.

For more details on finance packages, please call 01603 227838 or email: finance@haas.co.uk