Horizontal Mills

The Best-Value HMC in the Industry

Every Haas HMC provides the features and performance you need to boost your productivity, making it the best investment you have ever considered.

All the features and performance you’ve come to expect from a Haas

All Haas horizontal machining centres offer superior capabilities at affordable prices. With renowned ruggedness and reliability, you’ll find Haas HMCs are the perfect job shop machines for those looking to make more money in less time than ever before. The highly popular Haas EC Series HMCs offer large work cubes making them perfect solutions for your large-part machining requirements. Also available with an integrated 4th-axis rotary platter.

Do even more

From spindles to probe systems to multi-axis capability, Haas machines offer a toolbox of productivity-boosting options – because there’s no such thing as too much performance.

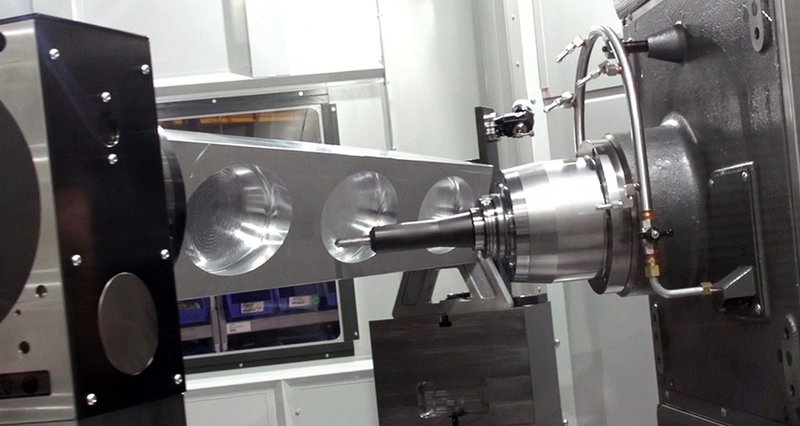

Spindles

Purpose built for Haas machines

Designed and manufactured in California by Haas, our spindles are custom-engineered for power, precision, and durability. We manufacture all spindles in-house using Haas machines. Mill and lathe spindles are roughed-out on Haas lathes in robotically tended cells. Final hard turning and threading are also completed on Haas machines.

Spindles are only as good as the electronics that drive them. We meticulously engineer our drive systems to provide the absolute best performance and reliability possible for our machine tools. At Haas, vertical integration isn’t just a buzzword – it’s a way of life.

Wireless Probing

Cut your setup times in half

Reduce setup times, work more efficiently, and eliminate waste due to misaligned parts when you use our Wireless Probing System (WIPS).

Our industry-leading Wireless Intuitive Probing System (WIPS) sets the standard for integrated probing systems. Easy on-screen directions guide beginning users through the process. Experienced users have access to the full power and capabilities of custom probe routines.

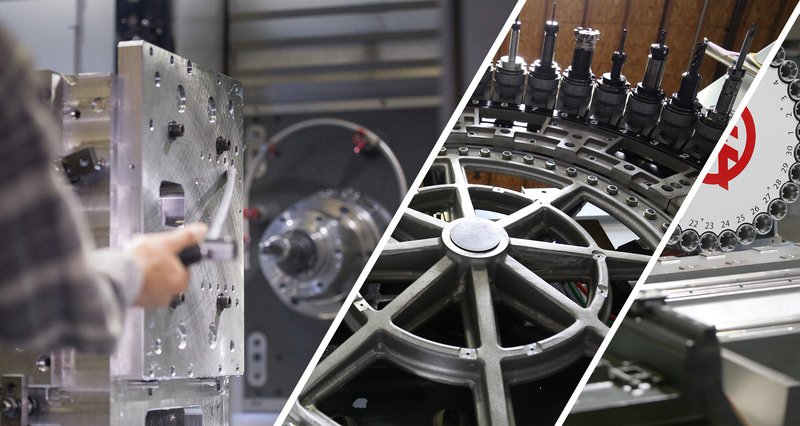

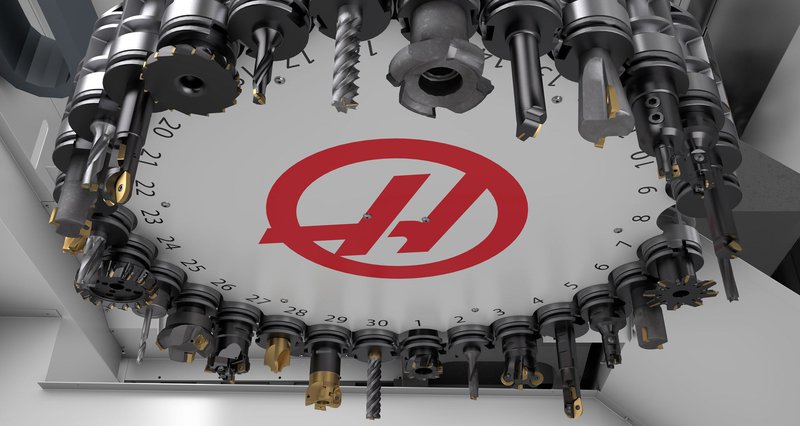

Tool Changers

Hold all the tools you need

From 30 to 50 pockets, we have a side-mount tool changer to meet your needs – designed in-house to guarantee accuracy and reliability.

Swarf and Coolant

Solutions for all swarf types

Load up your Haas horizontal mill with powerful tools for swarf clearing, coolant management, and swarf removal.

The Haas Control

Faster, smarter, and more powerful

The machine tool industry’s most user-friendly control is better than ever, and ready to help you create almost anything.

Multi-Axis Machining

3, 4, or 5 axis... We're ready...

All Haas horizontal mills are available with an option to retrofit a Haas rotary to create a powerful multi-axis machine for a fraction of the price giving you 4th and 5th Axis capability.