The industry-leading Haas VFs are the best-value, high-performance 50-taper vertical machining centres available today.

A Wide Range of Sizes and Features to Fit Any Shop’s Needs – Vertical Machining Centres

Haas offers a wide range of VF Series CNC 50-taper vertical machining centres to match any size and production requirement. Regardless of your needs, there’s a VF just right to meet the demands of your machine shop.

Every VF Series vertical machining centre provides outstanding features at an excellent price. By the same token there are a wide range of available options to customise your machine to your exact needs. Not to mention all Haas machines are designed and built in California, USA.

All large-frame models come with an upgraded features package that includes a side-mount tool changer, chip auger, programmable coolant nozzle, and remote jog handle.

- 50-taper spindle with 2-speed gearbox

- Customisable to your needs

- Our flagship model

- Made in the USA

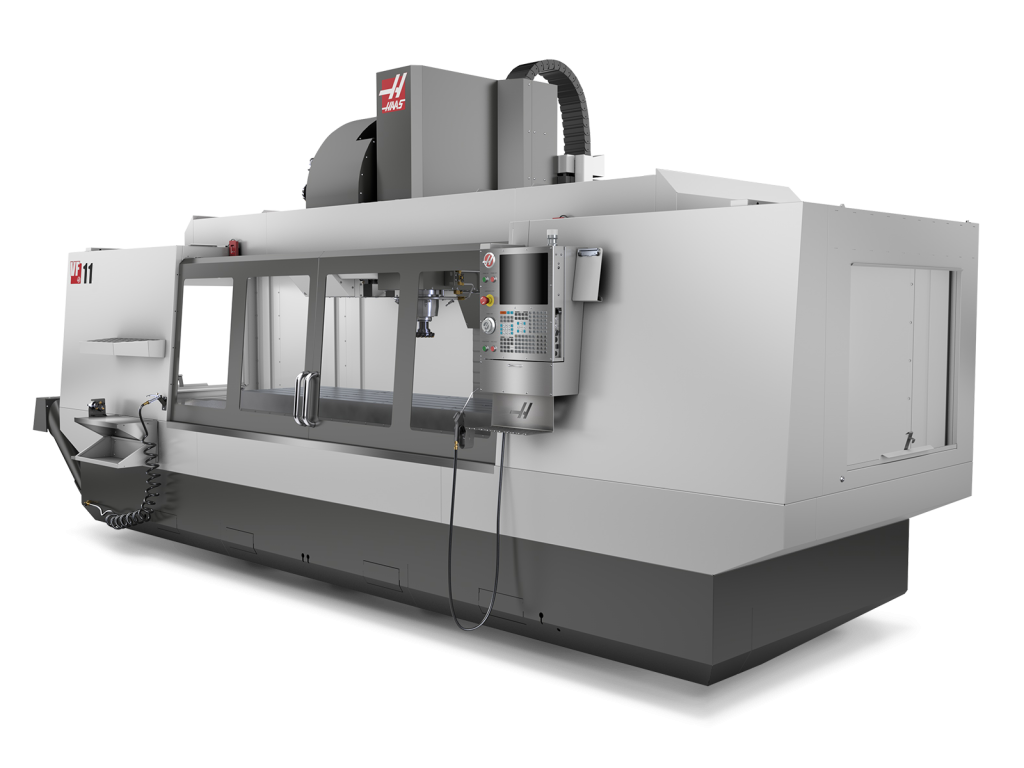

VF-11 50-taper Vertical Machining Centre; 3048 x 1016 x 762 mm, 50-taper geared-head, 30 hp vector drive, 7500 rpm, 30+1 side-mount tool changer, 9.1 m/min X rapids, 15.2 m/min Y & Z rapids, automatic chip auger, programmable coolant nozzle, colour remote jog handle, 15″ colour LCD monitor, USB port, Ethernet, memory lock keyswitch, power-failure detection module, 1 GB program memory, rigid tapping and a 360 litre flood coolant system. Outriggers standard. Anchor kit highly recommended for installation.

Haas 50-Taper Vertical Machining Centre at Work

This workhorse is well suited to high material removal rates, no matter what kind of cut you’re taking. The standard 7500-rpm 50-taper spindle has 30 hp, and the 2-speed gearbox delivers 450 ft-lb of torque at 500 rpm. This is perfect for drilling large holes, using wide shell mills, and any other demanding application.

Wireless Intuitive Probing System

Drastically reduce setup times on your high-speed machine

Automate your high-speed machine’s setup process with the Haas Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting probe, together with an optical machine interface. Furthermore, powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates. WIPS allows you to quickly also easily define work offset coordinates. Additionally, set tool length offsets, moreover perform in-process inspection.