Video: Haas Robotic Pallet Loader

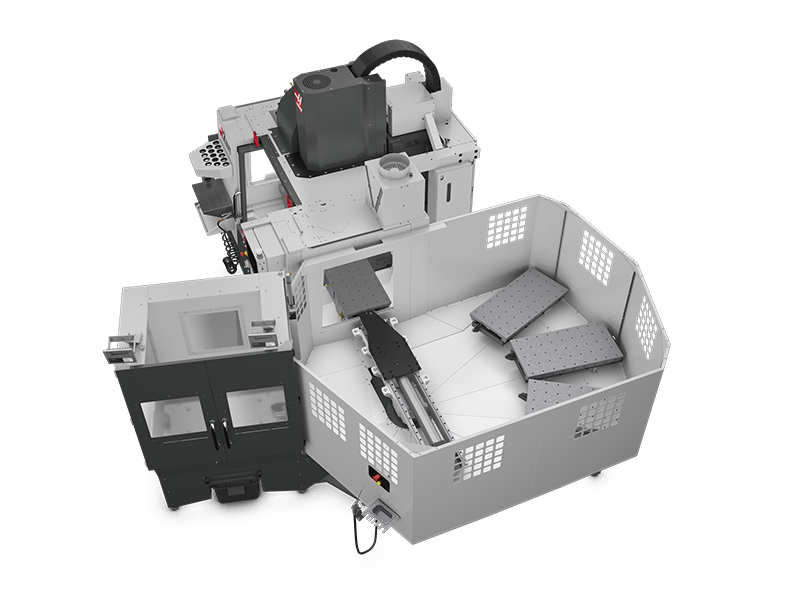

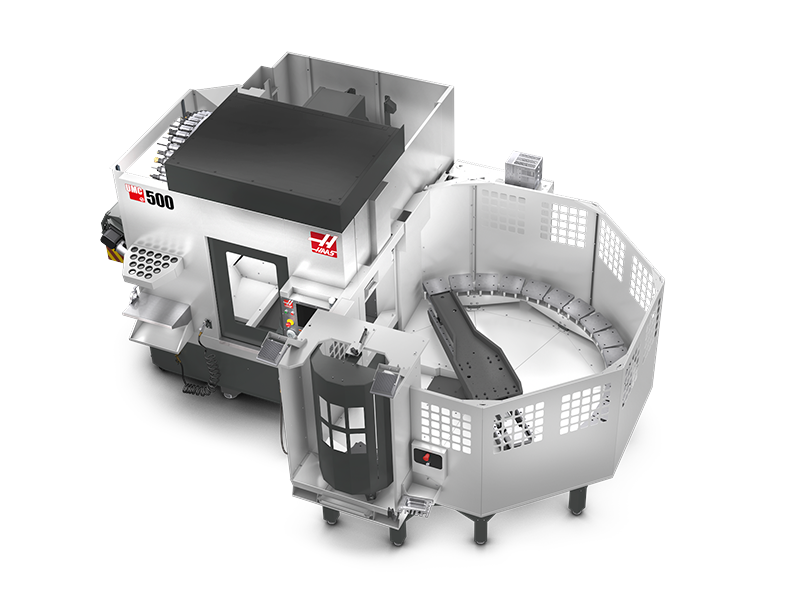

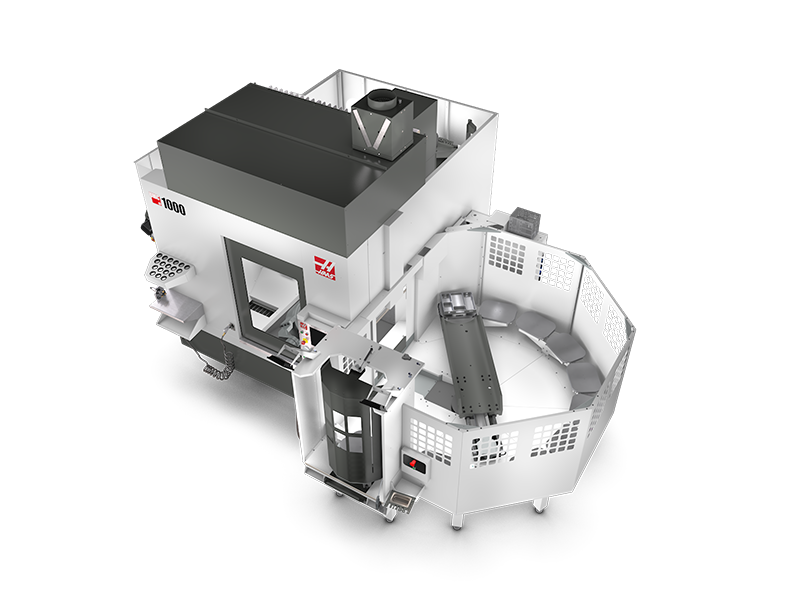

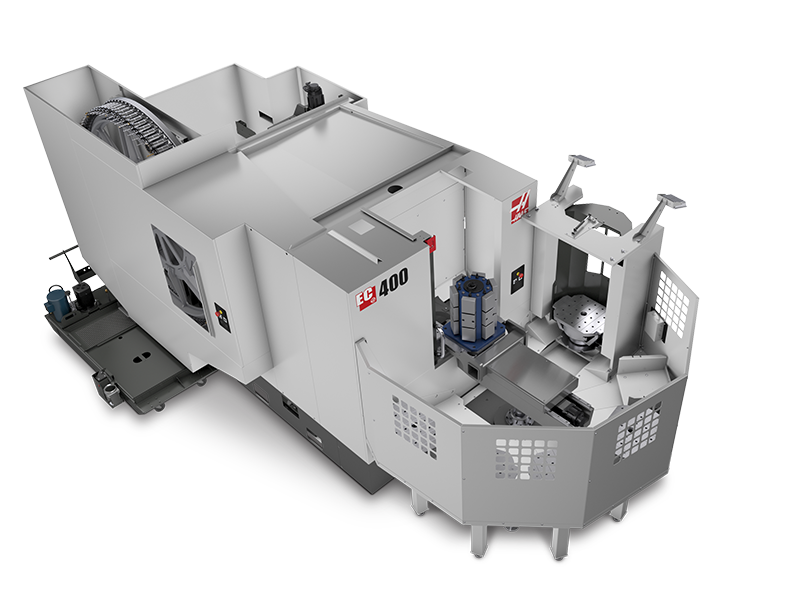

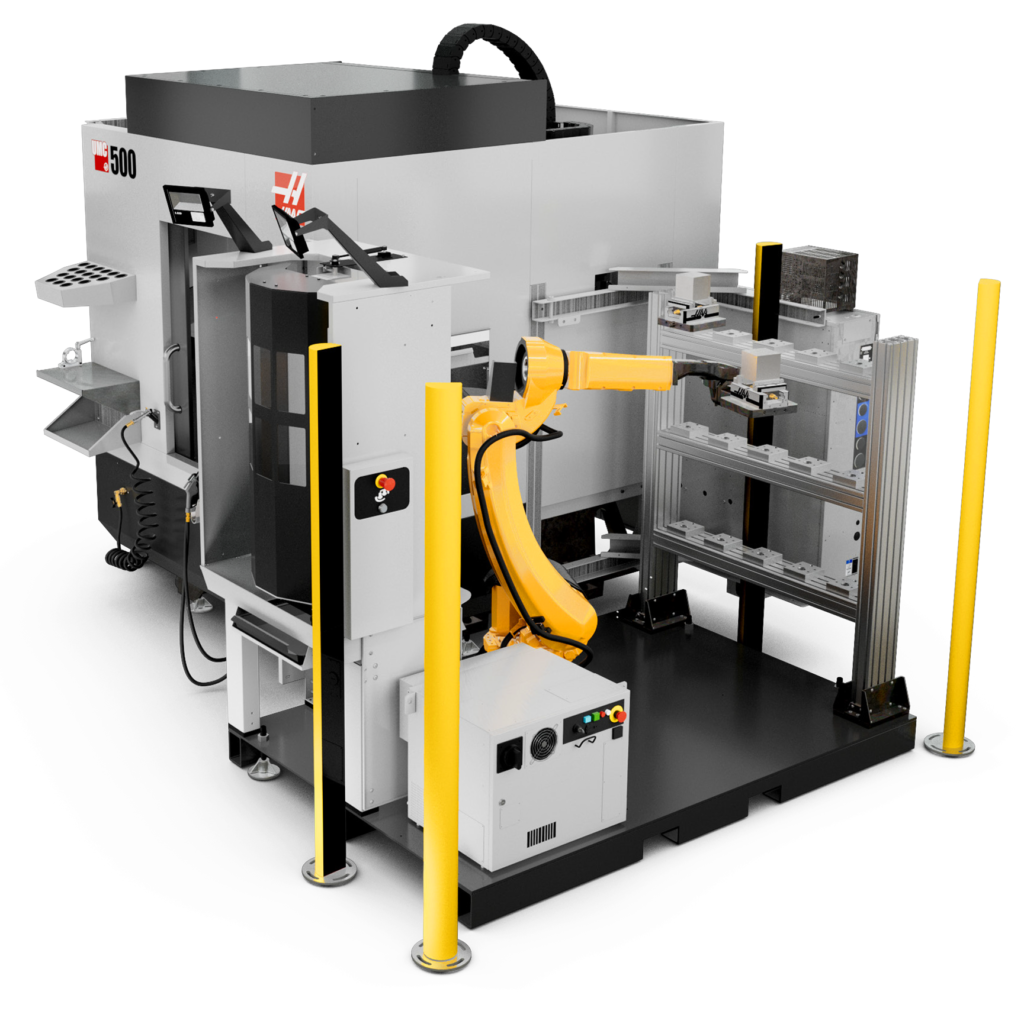

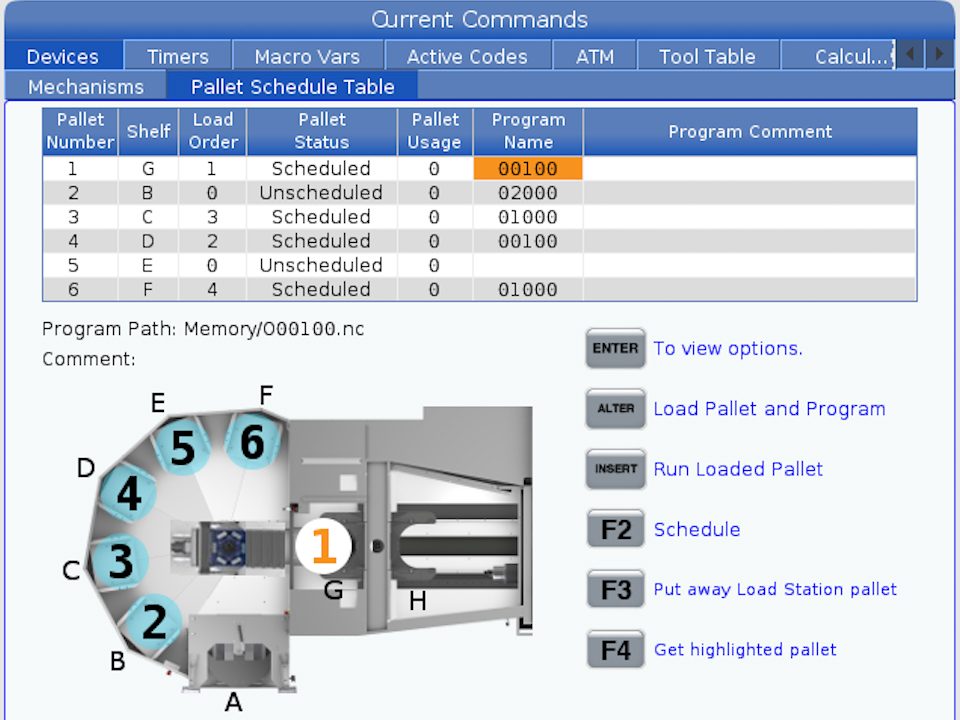

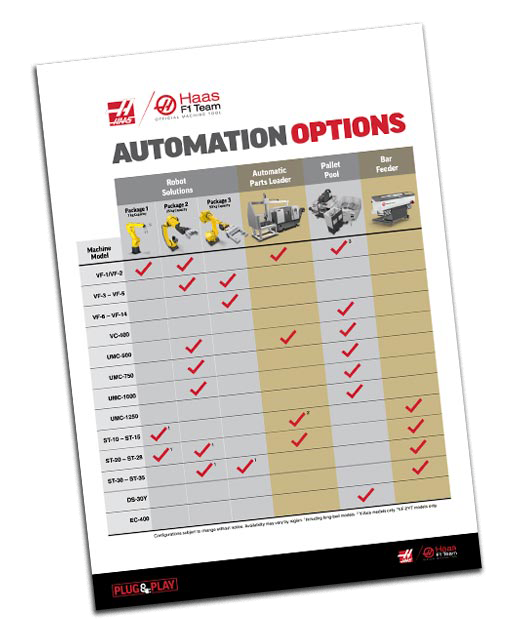

In this video, Mike introduces Haas’ new Robotic Pallet Loader. This scalable and affordable Pallet Loading System includes the Haas 25 kg capacity robot, loading station, light curtain, pallet rack, and 3 zero point pallets. The RPL is plug-and-play compatible with Haas UMCs, and small and medium VMCs. All set up and operation are done through the Haas control and remote jog handle.