Frank Brown and Son

Frank Brown and Son is an established and well-respected engineering company, specialising in the design and manufacture of ground support equipment for the aerospace and aircraft industry throughout the world.

Founded in 1966 by Frank Brown himself, the company began by doing general sub contract work for Vauxhall from a small unit in Luton.

Now, over 40 years later, the company is run by his son, Clive. After significant growth in the 1980’s Brown’s was moved to a new factory, totalling 10,000m2.

The business had by then become what it is today; a highly skilled designer of aircraft maintenance tooling and equipment.

Brown’s bought their first Haas machine in 1996. The VF-2D vertical machining centre ran every day until 2 years ago, when the team decided to part exchange it for a new VF-2SS Super Speed.

“We certainly got our money’s worth from that original machine,” says machine shop supervisor, Andy Knight.

“It was running well until its last day with us; it was always accurate, we just upgraded to something a bit quicker in the end.”

The machine shop has doubled in the last twenty years and with twenty Haas machines; six lathes and fourteen mills, the majority of our CNC machinery is supplied by Haas.

“Our workload has changed dramatically,” explains Andy. “Not so long ago we were making stock packs of ten a year, now its forty plus. And everything that needs machining goes on a Haas.”

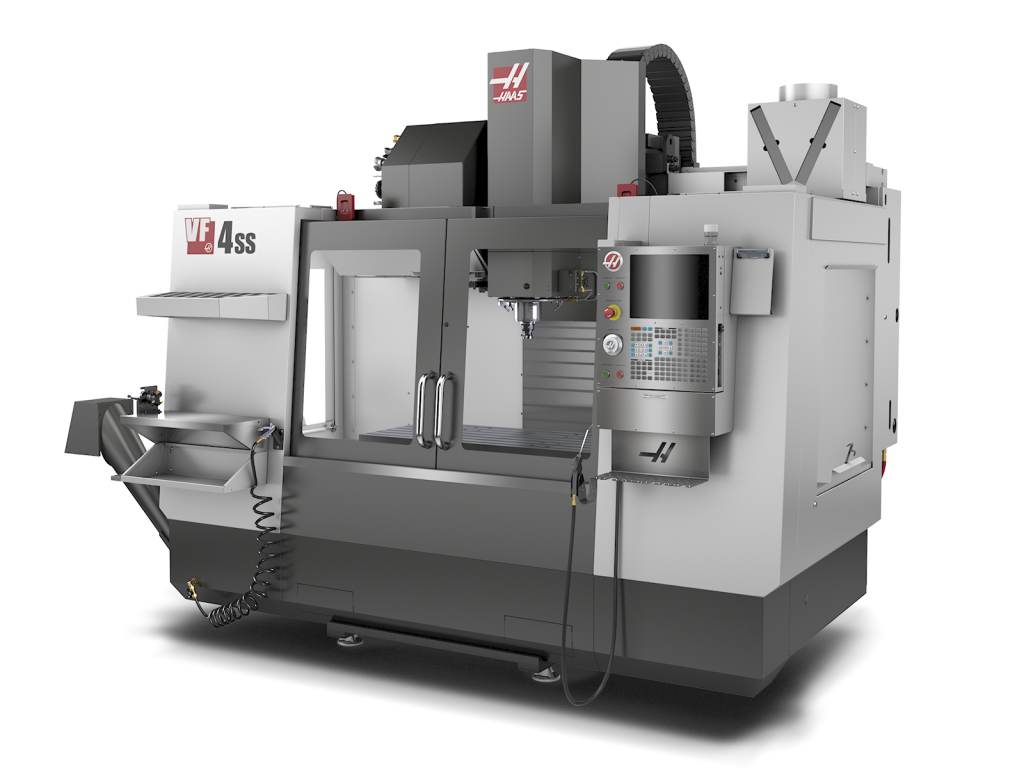

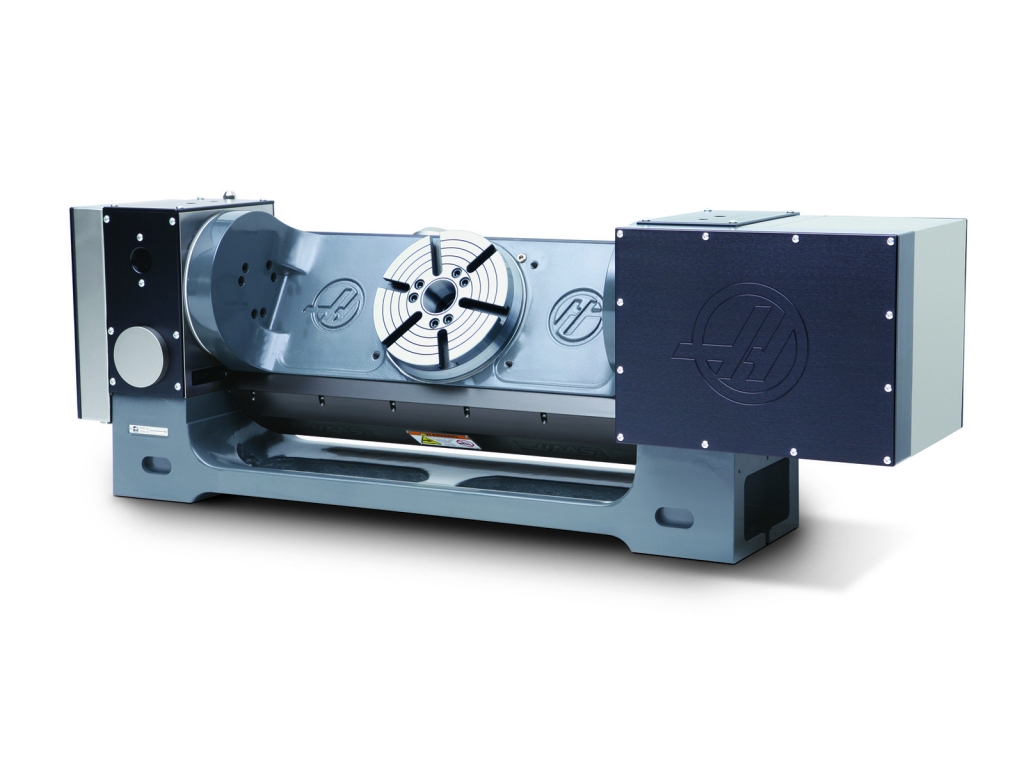

The latest investment is a VF-4SS with through spindle coolant and 5-axis trunnion. “The 5-axis machines are doing some really nice work. They cut our ops down from 6 to 2, which is a massive reduction.

“We’re producing a lot of Boeing 737 and Airbus tooling and it’s really made a difference; it’s knocking the stuffing out of the cycle times, cutting them by a third at least.”

In fact, Brown’s has purchased 4 Haas Super Speed mills in the last 4 years. “The rapids, tool change speed and 12,000 RPM spindle are phenomenal on the new machines,” comments Andy.

“We’re using CAD with long programs which have lots of movement, but they cope with them, no problem. Although,” he adds with a smile, “our oldest Haas is over 20 years old and it’s still mechanically very good. It’s a sound machine.”

When asked what the company’s plans for the future are Andy replies “To keep going and keep buying Haas. Clive has no intention of shopping anywhere else.”