Bowden Precision Engineering Ltd

Based in Fleckney, Leicestershire, Bowden Precision Engineering supplies to an expanding customer base mainly in the aerospace, medical, marine and punch & die industries. Continued investment in not just technology but its staff has enabled the company to maintain its high quality and keep its competitive edge in sub-contracting.

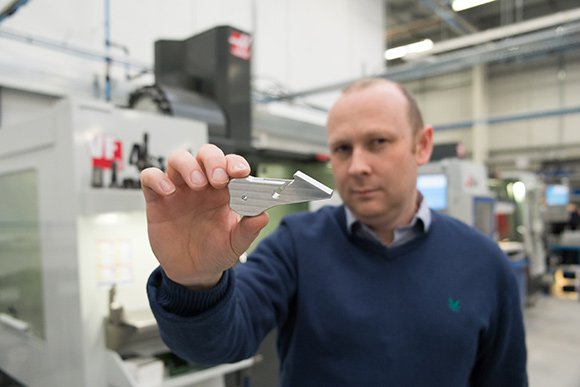

“Our highly skilled workforce can tackle anything; from a one-off copy of an existing part through to a large quantity of complex CAD components,” explains director Paul Barnett. “Our aim is to ensure complete customer satisfaction by producing accurate work of excellent quality, getting it right to tolerance and finish.

“We’ve earned a reputation for our professional and honest attitude and friendly ‘can-do’ approach to engineering. This, combined with our workshop capacity ensures our customers receive an excellent product – on time and on budget.”

In 2013 Bowden became part of the COBA International group and in 2014 moved into a new purpose built facility. “This has been a real milestone moment for Bowden Precision. The company was founded in 1982 and built it up from those initial modest beginnings to the successful business you see today.

“As well as our precision engineering expertise and CMM inspection capabilities, we pride ourselves on our efficiency and teamwork,” continues Mr Barnett. “We have a fully documented system of in process and final inspection procedures, which are rigorously implemented to ensure all components, are manufactured to tolerances given.”

Bowden Engineering currently employs 9 staff, including 6 fully skilled CNC programmers. “Finding skilled staff can be very difficult,” states Mr Barnett. “By offering training to young people from local schools and colleges we’re investing in the next generation of UK engineering and manufacturing talent.

“The most recent addition to our team, Adam, approached us and asked if he could come in and get some hands on experience. We were so impressed by his enthusiasm and thirst for knowledge we decided to offer him a job. He still attends college and has been on the Haas training course at Leicester. Our skilled staff enjoy mentoring Adam; passing on their knowledge gives them a real sense of fulfilment.

“It’s vital to have the right skills, we’re lucky to have programmers and operators who are in perfect harmony with our machines. This gives us a confidence in our capability, and our customers have confidence in us.

“We are getting more and more involved in our customers’ design and development stage. They are often very good at designing a 3D model, but need a lot of assistance when it comes to manufacturing processes. Using a combination of SolidWorks and OneCNC we help them to ‘design for manufacture’ enabling their ideas to be produced more simply and therefore more economically.

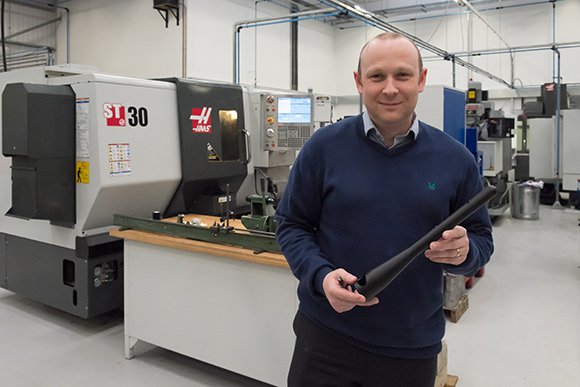

“I can attribute a lot of our success to the fact that we have heavily invested in Haas CNC machines. In the last 18 months alone we’ve installed three Haas mills and a Haas turning centre. It’s safe to say that they’ve become the backbone of our company as far as milling and turning is concerned. Haas machines offer the perfect balance between flexibility, quality and value. We’re delighted with the accuracy, repeatability and cycle times we’re achieving.

“We have plenty of space to expand and have plans to fill it with more CNC machines. When we do we’ll put more Haas machines in it, because they’ve served us well.

“It’s an exciting time for Bowden,” Mr Barnett concludes. “We’ve changed more in the last couple of years than in the previous thirty. As our range of products has become more technologically innovative, so has our approach to their production. Thanks to the Haas machines and the changes we’ve made as a company, we’re doing things quicker, better and more efficiently whilst also improving quality.”

We have plenty of space to expand and have plans to fill it with more CNC machines. When we do we’ll put more Haas machines in it, because they’ve served us well.

Paul Barnett, Director