COM Engineering

Harnessing technology, for a safer future

Brothers Craig and Mark Stevens design and manufacture electronic security equipment. Used around the world in places such as airports, protecting recognised locations of high risk, public safety and crowd monitoring. Their Chester based company, Megablue Technologies, had been operating for seven years when they decided to expand their operation. To meet the needs of their clients, COM Engineering was founded in 2016, designing specific enclosures for their products.

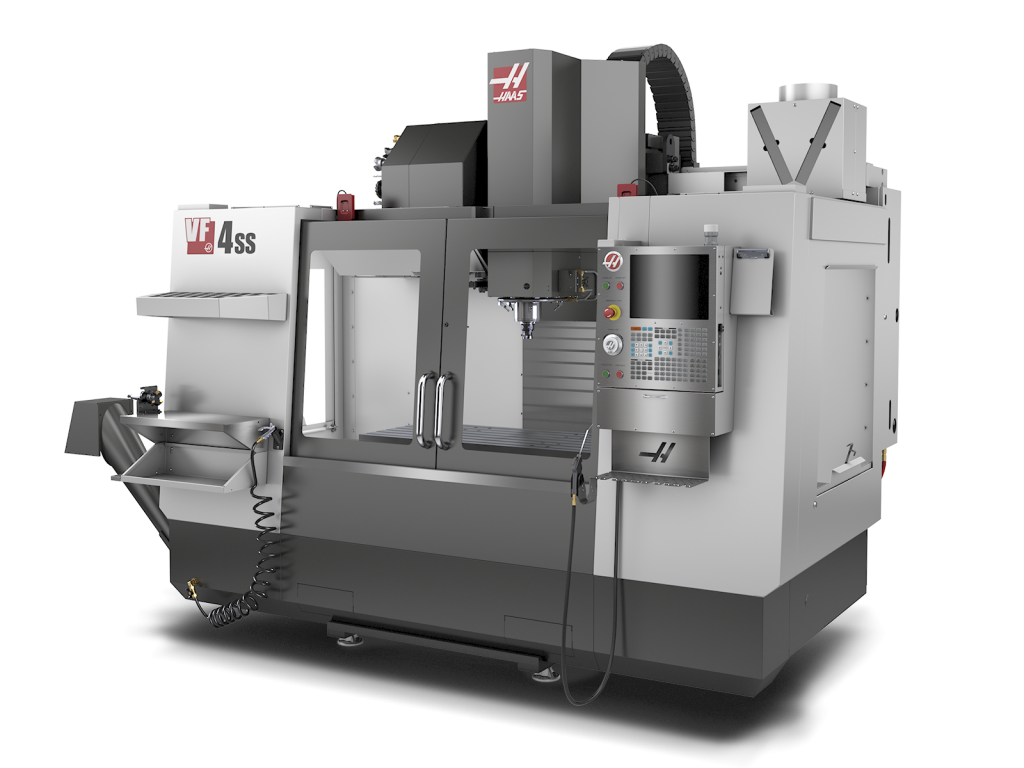

The team of eight at COM Engineering have seen a ten-fold increase in business since the company’s inception. “We wouldn’t have coped with the volume of orders without the Haas,” says Craig. “It’s incredible what a difference the 12,000 rpm spindle makes, and feed rates are four times faster. The machine is making things we wouldn’t have believed possible, and the finish is fantastic.”

The 1,270 x 508 x 635 mm table means that space can really be optimised. “We regularly have up to eight parts on there in one go and there are always four vices on the table, together with a probe. Constantly changing the workpiece would be very time consuming, so we opted for the WIPS (Wireless Probing System); it makes the set-up three times quicker.

“We did a lot of research before choosing which machine to buy; we had it narrowed down to two but the Haas salesman (Ian Lowe) was so helpful and very responsive, it gave us the confidence to go with Haas. Also, the machine is compatible with Fusion 360 and Mach 3, which I use to design a lot of our products. I like the fact that I can sit at my desk and design an enclosure, then send it straight to the control on the VF-4SS and my operator completes the process; it’s simplicity itself.

The team of eight at COM Engineering have seen a ten-fold increase in business since the company’s inception. “We wouldn’t have coped with the volume of orders without the Haas,” says Craig. “It’s incredible what a difference the 12,000 rpm spindle makes, and feed rates are four times faster. The machine is making things we wouldn’t have believed possible, and the finish is fantastic.”

The 1,270 x 508 x 635 mm table means that space can really be optimised. “We regularly have up to eight parts on there in one go and there are always four vices on the table, together with a probe. Constantly changing the workpiece would be very time consuming, so we opted for the WIPS (Wireless Probing System); it makes the set-up three times quicker.

“We did a lot of research before choosing which machine to buy; we had it narrowed down to two but the Haas salesman (Ian Lowe) was so helpful and very responsive, it gave us the confidence to go with Haas. Also, the machine is compatible with Fusion 360 and Mach 3, which I use to design a lot of our products. I like the fact that I can sit at my desk and design an enclosure, then send it straight to the control on the VF-4SS and my operator completes the process; it’s simplicity itself.

“An added bonus was going to the Haas F1 Team facility for our training. The course was very good and included an element of manual machining, which helped our operators to fully understand. We then got to quiz the instructor on specific queries during our day of on-site training, back at our factory.

“We’ve found the after-sales support very impressive too. We had what I shall call a ‘learning curve’ with a G55, which knocked out the spindle. But the Haas engineer came out immediately and found that we hadn’t done much damage. He was organised, efficient and he fixed it straight away.

“The Haas has revolutionised our manufacturing process,” concludes Craig. “We have an enclosure, a very robust cube of solid aluminium, which we now make in two pieces. One of those used to be made in five separate parts, now it’s just one. What can I say? We’ll be placing another order with Haas in the next few months.”

“I like the fact that I can sit at my desk and design an enclosure, then send it straight to the control on the VF-4SS and my operator completes the process; it’s simplicity itself.”

Craig Stevens