Investment Castings (Congleton)

Investment Castings are a leading supplier of quality castings with over 50 years experience in the industry. They offer a complete in-house service incorporating design, tooling, rapid prototyping, casting and finishing.

The manufacture of castings involves several highly skilled processes. First, the tool maker produces the aluminium die, and high-technology wax is injected into it. The wax components are then mounted and dipped (or invested) into a binder, coated in silica sand and dried in a temperature-controlled environment.

Layers of ceramic particles are then added until the mould is of the required thickness. Once completely dried the wax is melted, leaving the ceramic shell. This is often called the lost wax process. The shell is fired at 1,000°C and is filled with molten metal to create the casting. Once the metal has cooled the ceramic shell is removed, leaving a casting that requires little or no finishing.

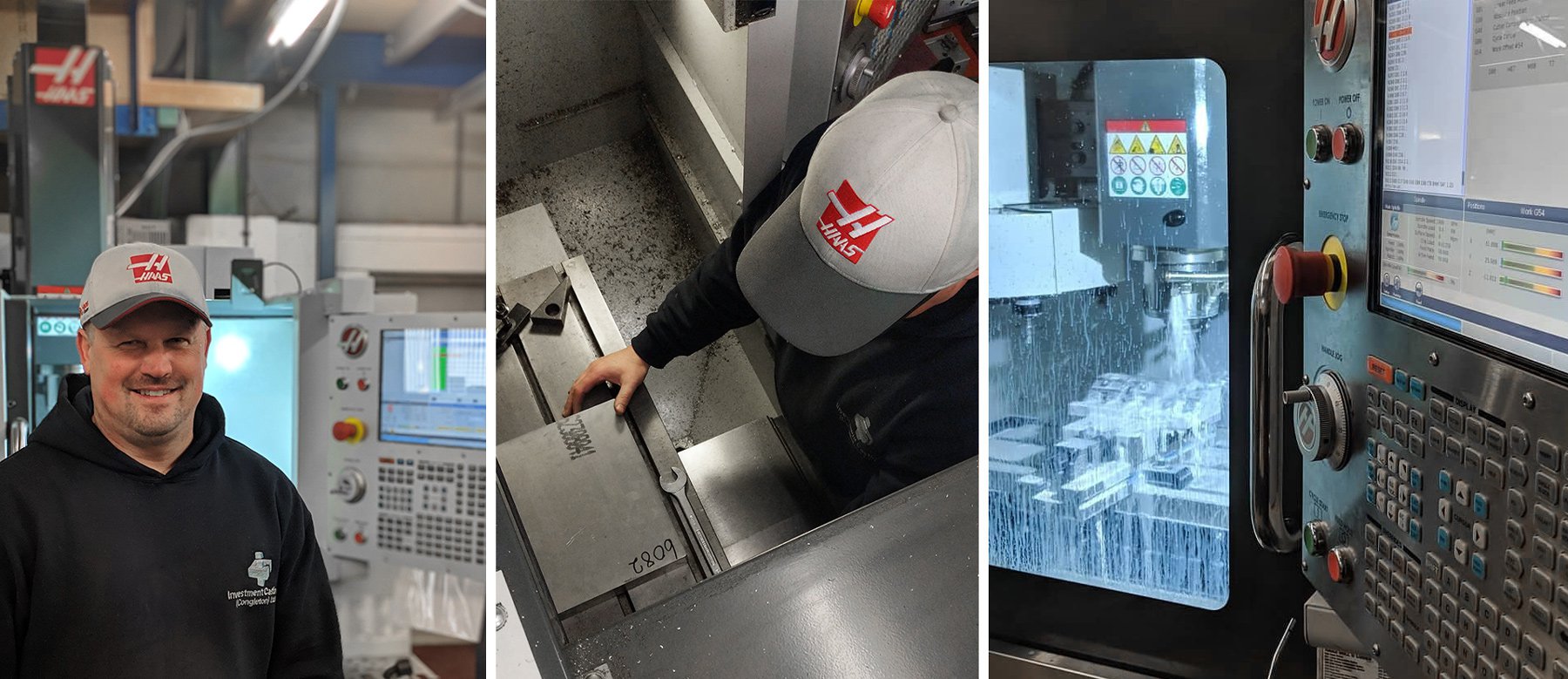

This method has been used at Investment Castings since Brian Clarkson founded the company 30 years ago. Now sons, Paul and Dave, head up a team of 20, including a full-time toolmaker and his apprentice.

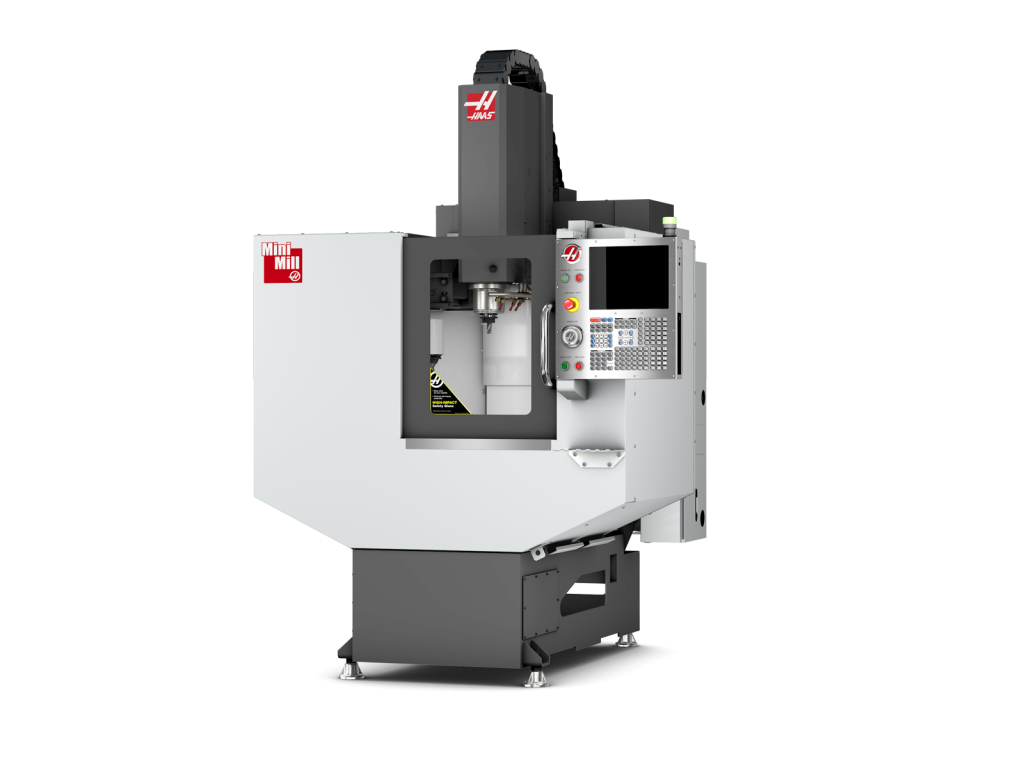

In 2010 the factory in Congleton, Cheshire was underwent a large expansion and the old CNC machine, used to produce the aluminium dies, was replaced with a Haas Super Mini Mill. Within a year they had added a second and now have five CNCs at their disposal, all of them from the Haas Mini Mill range.

“Five machines are more efficient than two large machines in the same space.”

“We chose Haas after being impressed with them at trade shows, and found they were very competitively priced”, explains Company Secretary, Suzanne Clarkson. “The first machine made a huge difference to our business in terms of the complex machining services we could offer and reduced lead times for tool production.

“We were aware that the service and backup was efficient which is very important to us. Haas makes a small machine, which was ideal for the space we have. Five machines are more efficient than two large machines in the same space.”

The company’s list of 300 customers covers a diverse range of industries from projects for Bentley and Aston Martin, to hoist systems used in hospitals and even sword guards and pommels used in battle re-enactments. “We also do a lot of rapid prototyping, especially for the automotive industry, for Formula 1 and Indy Car teams. This allows customers to trial new designs very quickly and helps us to secure orders for permanent tooling.”

Designs for the tools are created using OneCNC and Solid Edge Cad Cam systems and sent directly to the Haas machines via ethernet.

“We leave machines to run overnight and can make multiple tools at once now. And with the 10,000 rpm spindle and 20+1 high-speed tool changer, our lead times are massively reduced, while the quality increases. We can achieve far better finishes on parts and tools because of the high-speed spindles.”

Investment Castings take pride in offering 100% UK manufacturing; never out-sourcing abroad. Suzanne says “We’re one of only a handful of UK investment casting manufacturers still in the business; many have lost out to cheaper products imported from China. Our customers come to us because we are genuinely manufacturing from start to finish, we provide complete traceability.”

VIDEO – Haas Mini Mill

Haas Product Specialist Bryan O’Fallon and Engineering Manager Bob Draper discuss the newly redesigned Mini Mill. This super popular small-footprint machine has proven successful in small and large shops alike, and Bob and Bryan talk about the improvements that were made to increase reliability and make the new machine even easier to use.

“Haas makes a small machine, which was ideal for the space we have. Five machines are more efficient than two large machines in the same space.”

“We chose Haas after being impressed with them at trade shows, and found they were very competitively priced. The first machine made a huge difference to our business in terms of the complex machining services we could offer and reduced lead times for tool production.”

Suzanne Clarkson – Company Secretary