Lyndhurst Precision

Saving lives is all part of a day’s work for the design and manufacture team at Lyndhurst Precision. Their bespoke engineering solutions have covered countless projects in the company’s 30 year history. Their minefield breaching device is one they are particularly proud of. A trusted favourite of both medical and military personnel, the device allows for rapid advance through booby-trapped areas, ensuring a clear path to safely reach the regions most in need.

Also capable of making a life-changing difference is Lyndhurst’s medical dressing assembly machine, which is currently used both in hospitals and in the field. Challenged with designing, manufacturing and installing a system to assemble various medical dressing components was no simple task. Using cutting edge electro-mechanical positioning activators together with a pallet transfer system to create a high-speed process that delivers accurate finished components, the machine passes rigorous testing procedures you would expect from the medical industry.

Ian Lowe (Haas Automation) and Stewart Walker (Lyndhurst’s Operations Manager)

Lyndhurst serves a diverse range of sectors including automotive, nuclear, defence and renewable energy. They have recently completed a conveyor system for a Japanese automotive facility in Thailand, and have now begun the mammoth task of building a test area to safely decommission a nuclear facility.

Everything is created using CAD system, Inventor. “We don’t have a product. We enable others to have a product”, says Manager, Ruth Marriner. Lyndhurst’s 50 employees include a diverse team of designers and engineers able to adapt to the myriad of challenges required of them.

Lyndhurst’s medical dressing assembly machine

With humble beginnings, the company’s first workshop was housed in a garden shed. Substantial growth has led to a purpose-built factory in Chorley, Lancashire and Lyndhurst are accustomed to working for small businesses, multinational corporations and governments alike. Turnover has increased by 30% in the last year and the workforce by 10%, signalling the need for investment in new equipment, including their CNC machines.

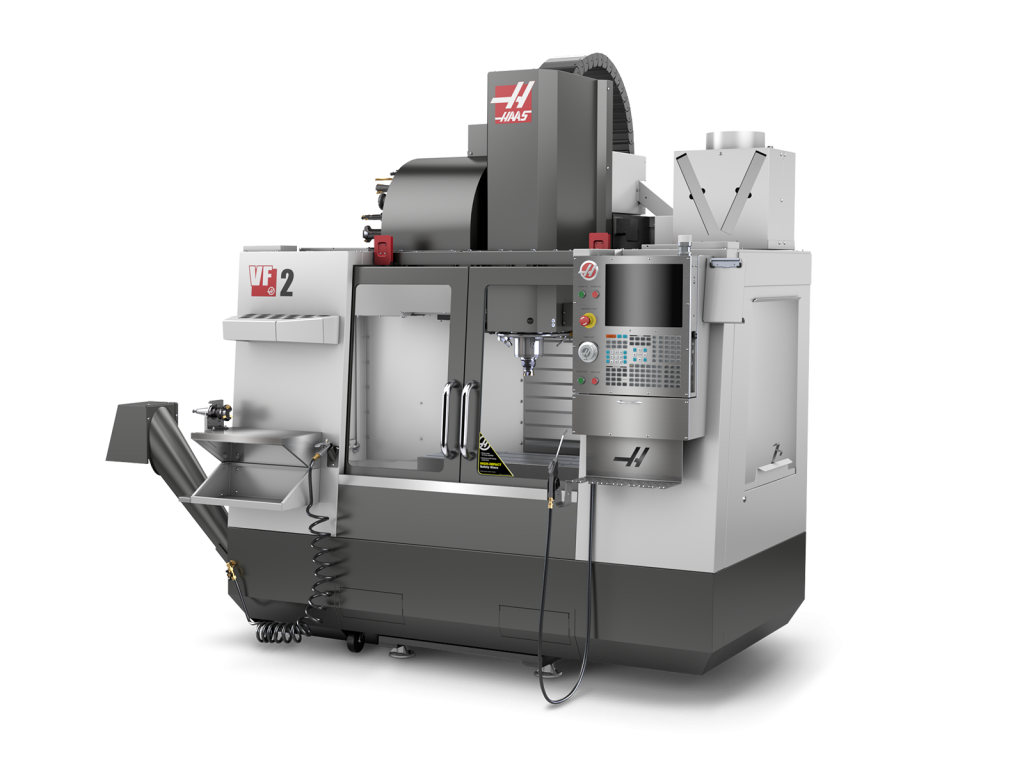

After a recommendation from a local company, Lyndhurst looked at Haas. “It was immediately obvious that Haas produced a quality machine,” says Ruth. The team opted for a VF-2 vertical machining centre, with an ST-15Y turning centre soon to be delivered. The VF-2 is loading with an 8,100-rpm spindle and 20 station carousel tool changer. The ST-15Y has full Y axis capacity, a 4,000 rpm A2-6 spindle, can handle 2.5” (63.5mm) bar and comes with a 12 station VDI turret.

“The VF-2 is a faster, more accurate machine. The machinists love working on it; they say they’re lucky to have it in the factory. We design and build everything in-house; it enables us to give a better customer to client service. We don’t want to grow big, we want to grow better and the machine has made us more efficient and has increased the quality of the final product.