EBC Brakes - Haas CNC increases stopping power!

Whether you are straddling a 1,000cc superbike hurtling at 200 mph toward one of the countless turns of the hallowed 37.7-mile Isle of Man TT mountain course, somewhere in the Mexican desert approaching the Ensenada finish line after 20 plus hours running non-stop in the gruelling Baja 1000 or pedalling a bicycle down a steep, root-studded, rocky descent having just landed a drop off at the infamous Mont-Sainte-Anne course in the Mountain Bike World Cup, probably top of your list of components you would rather not fail are those within your braking system.

EBC Brakes produces the largest range of brake pads and brake discs in the world, with over 5,000 part numbers for every type of vehicle, manufactured in one of its two specialist factories in the UK and USA.

The firm has been manufacturing high-performance braking components at their Northampton World Headquarters for nearly 40 years.

In addition to the brakes used in various racing classes, EBC Brakes produce a comprehensive range of braking products for road and track cars, road and track motorbikes, quadbikes & ATV’s, mountain bikes, trains and commercial vehicles.

Central to production are their Haas CNC machines. Research & Development Manager, Adam Freeman says, “We chose Haas because we love the fact the machines are built in the U.S.A. As a company that is built around manufacturing in the UK and the U.S.A. we want to choose suppliers that align with our company’s ethos. Investing in Haas – who were selected over a number of competitors – has allowed us to take full control of our manufacturing, letting us machine all components in-house.”

The Haas DS-30SSY Super Speed, Y axis, dual-spindle lathe is used to machine the disc hubs of the two-piece discs for the performance braking division of the business and allows turning of both sides and drilling of mounting holes live.

The two-piece disc, a steel rotor with an aluminium hub, is used predominantly to save weight and improve braking performance at the extreme temperatures seen on track or during fast road driving.

To solve the issue of the rotor fluctuating in size as it heats or cools, EBC use an SD (square drive) system, allowing the rotor to slide against the hub as it expands or contracts and therefore avoiding warping.

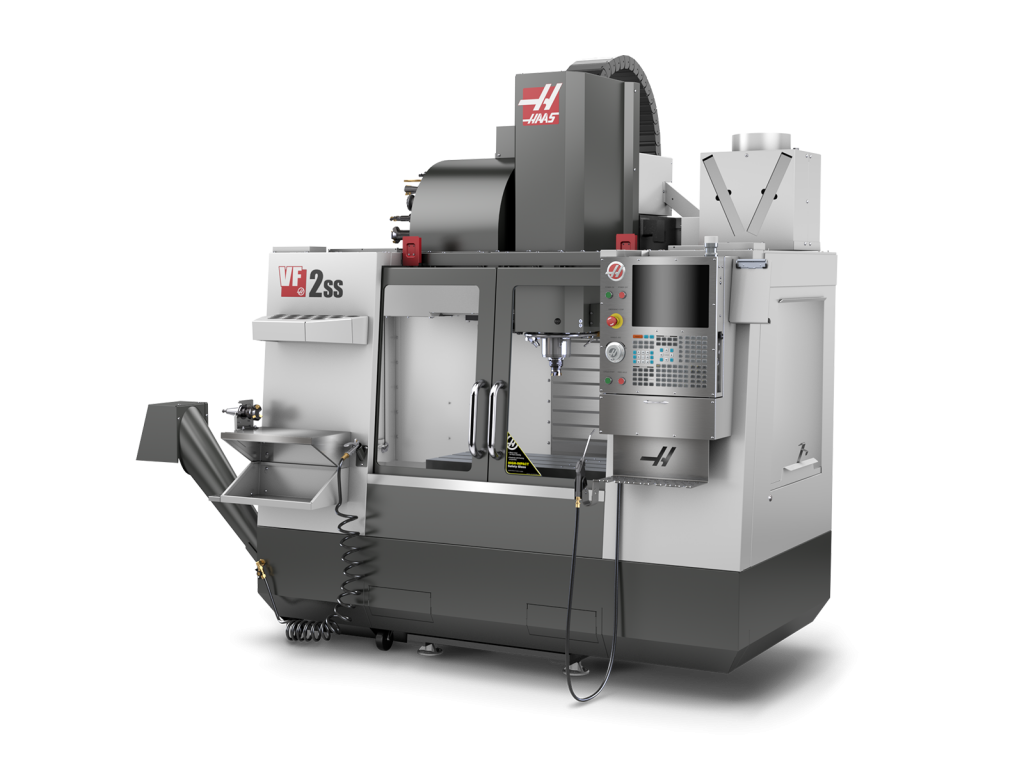

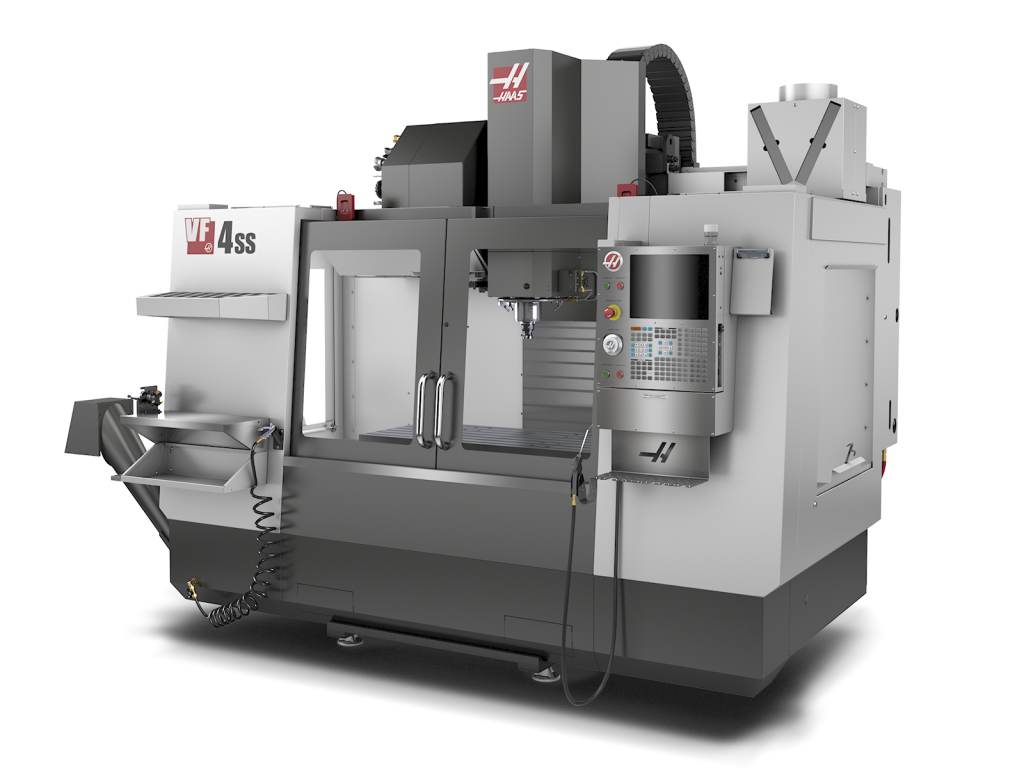

The DS-30 is supported by the company’s Haas VF-2SS and VF-4SS vertical machining centres, which are housed in the brand new machine shop, the EBC Centre of Excellence.

This state-of-the-art facility is used as an R&D tool as well as for production of EBC’s new line of performance brake calipers, two-piece floating discs and big brake kits.

The new division is the creation of the owner’s son, Adam, who has taken the company forward into high performance braking.

EBC’s latest acquisition is an ST-20Y lathe which comes with a 4,000 rpm A2-6 spindle, a 12 station BMT65 turret and high-torque live tooling.

“The Y-axis lathes give us great flexibility in our R&D sector,” enthuses Adam. “The additional axis removes the second operation on the milling side; it gives us a very quick turnaround for prototyping and testing.

“We’d seen the benefits of using a Y-axis lathe with our DS-30SSY, so it was an easy decision for us to invest in the ST-20Y.”