Precision Production at Edelbrock

Precision Production Keeps Edelbrock in the Winner’s Circle

When Vic Edelbrock bought his first project car in 1938, he had no idea he was about to revolutionise the world of hot rods. He just wanted to make his ’32 Ford roadster the fastest car around.

Working out of his small garage in Los Angeles, he designed an intake manifold called “the Slingshot” for his flathead Ford. After strapping the manifold and a pair of Stromberg 97s to his engine, he headed to Muroc Dry Lake (where Edwards Air Force base is today) for testing and racing.

The “Slingshot” propelled the little deuce roadster across the desert at 121 mph, and into the winner’s circle, signalling the beginning of the Edelbrock dynasty.

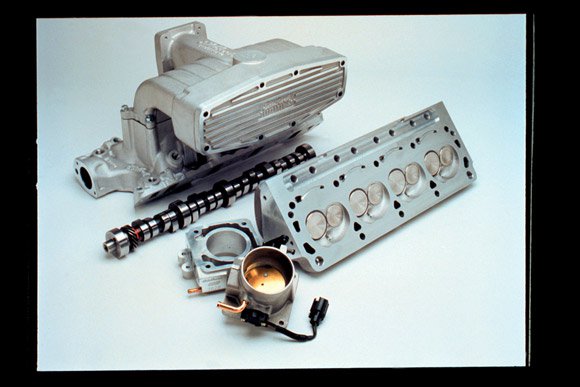

Today, Edelbrock Corporation remains in the winner’s circle as the premier manufacturer of high-performance aftermarket automobile components. The Torrance, California-based company produces more than two thousand different products, all designed to give their customers proven performance and maximum horsepower.

Top NASCAR teams, including Hendrick Motorsports, rely on Edelbrock components in their race cars. On the street, they set the standard by which all other parts are judged. Every time a driver starts his or her engine, Edelbrock’s reputation is put to the test. And time after time, their intake manifolds, cylinder heads, camshafts, water pumps and other performance products meet the challenge and come out on top.

With so much riding on the line, the 500-plus-employee company leaves nothing to chance. “Controlling the process from start to finish is the best way to guarantee our products do what we say,” says Scott Herrmann, Automation Systems Specialist at Edelbrock. “And having the most up-to-date tools to design and manufacture these products assures they are the best they can be.”

Herrmann arrived at Edelbrock fifteen years ago to manage the quality aspects of manufacturing, from initial product development through shipping the parts out the door. His engineering degree in aerospace and background in computers and automation made him the ideal candidate to guide Edelbrock into the high-tech era of machining.

”When I first started working here,“ said Herrmann, ”there were only 65 employees and no CNC machines. I began at the bottom doing the programming, then trained other people to program and do setup. Now, we’ve got a PC-based network linked to 25 precision machines, and we have a half dozen setup guys and manufacturing engineers.“

Today, the 135,000-square-foot Torrance facility houses a gamut of CNC machines, including a five-axis Haas VF-6 vertical machining centre used exclusively for porting cylinder heads. A Haas VF-2 and two VF-3 vertical machining centres equipped with 4th-axis rotary tables are used for completing practically every product Edelbrock makes, from cylinder heads and intake manifolds to water pumps and carburetors.

According to Herrmann, they use the VF-2 and two VF-3’s for all the secondary operations they can’t do on their two Mori Seiki horizontals, either because they don’t have enough tools, or because the cut is located on the bottom of the part and would require refixturing. “The Haas machines fit our production flow nicely and finish the parts to a high quality,” said Herrmann.

Manufacturing is about getting product out the door, and Edelbrock has it down to a science. They produce about 5000 intake manifolds a week (10 to 20 different models), 200 sets of cylinder heads (various models), and 200 water pumps (again, three to four different models). For Herrmann, this translates into dealing with 20 to 25 setups a week.

“We’ve selected the right combination of machines, so now it’s a question of reducing setup time. And the Haas units have helped us do just that. Each time I bring a Haas machine on-line, I notice an immediate increase in productivity. I attribute this to their ease in setting up, and because they are easy to teach people how to operate.

“A feature we find especially helpful,” continues Herrmann, “is the jog handle scrolling. It allows our setup guys to zip down the program on the control screen to make changes. It is a lot quicker than using arrow keys. We wish other CNC machines had that feature.”

Herrmann purchased Edelbrock’s first Haas machine, the VF-2, in 1994 to replace an existing machine that was getting old and worn out. For the application, he looked at Mori Seiki’s small line, Cincinnati Milacron’s small line, Fadal Engineering and Haas. “I chose the Haas,” said Herrmann, “because it fit our application and tight space requirements. For the money, it was the best and most reliable.

“We run 24 hours a day, 5 days a week, so reliability is a big issue with us, along with service and support. If a machine goes down, we need responsive service to prevent lapses in production. “I know Haas will be there to respond if I call.”

Last year when Herrmann needed a 5-axis vertical machining centre to perform one of Edelbrock’s most critical machining functions – porting aluminum cylinder heads – he returned to Haas and purchased a VF-6 equipped with high-speed machining and inverse-time options for 5-axis operation, and extended memory to handle their huge files.

“When a customer buys a product from Edelbrock, they are looking for bolt-on performance,” said Herrmann. “It is important that the cylinder heads in production generate the same amount of power as the prototype. This requires precision accuracy and repeatability.”

The more consistent the cylinders are, the better. On a V-8 engine there are two cylinder heads, which means eight cylinders. When the cast- aluminium heads arrive from the Edelbrock foundry in San Jacinto, California, the cylinders can vary up to 30 thousandths of an inch. According to Herrmann, this would work fine for the average engine, but for true performance, each cylinder needs to have exactly the same parameters.

Herrmann said, “Craftsmen can grind cylinders by hand, which makes them close to perfect, but when you port them with a CNC machine, every cylinder is perfect and exactly the same. Each cylinder is going to flow the same and the distribution is going to be equal to all cylinders. That type of precision and consistency is critical to our customers.

And it’s critical to the continued success of Edelbrock. Like Haas, they are an American company that is thriving because they engineer good products, manufacture good products and support their products. “Our company is based on guaranteed performance,” said Herrmann. “We sell nothing less and expect nothing less from the companies we work with. That’s the secret.”

We run 24 hours a day, 5 days a week, so reliability is a big issue with us, along with service and support. If a machine goes down, we need responsive service to prevent lapses in production. I know Haas will be there to respond if I call.

Scott Herrmann, Automation Systems Specialist