The Attysmith - Squonkers, Attys and Hellfire Mods!

Squonker, Stumpy, Atty and Whistle-Tip could easily be mistaken for characters in a Lord of the Rings style fantasy novel, rather than products from the more down-to-earth world of vaping. However, as vaping continues to gain popularity, these strange sounding names are becoming more familiar to an ever-growing audience.

When Darren Lyons decided to give up cigarettes, vaping caught his attention and seemed a reasonable alternative. Although he actually found the vaping experience to be disappointing. Determined to improve the taste and the feeling he began designing and developing his own equipment.

Darren soon realised that other people shared his views and after some intensive research and development The Attysmith Company was born. Known as Hellfire Mods, the products provide a unique vaping experience, offering over 300 products, including hand-crafted atomisers, hybrids and drip tips.

Designing every unit himself from his factory in Ballynahinch, County Down, Darren’s business has snowballed in the five years he has been operating. “We’ve been expanding steadily,” explains Darren. “We put the profit back into the business, which means we can continuously invest and improve.”

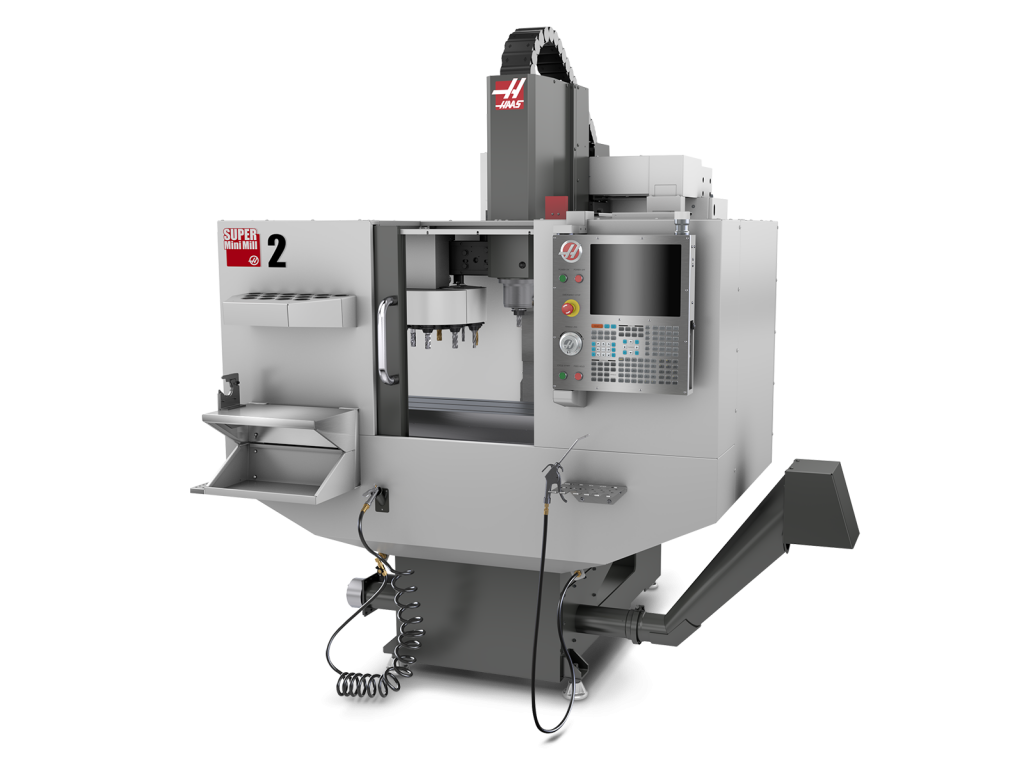

In 2014 Darren decided the company needed a CNC machine. “I’d always liked the look of Haas,” he says. “As it was our first we were a little nervous but Chris Cole, our Haas salesman, guided us through the whole process. He really knows his subject.”

Now with seven CNCs at his command, all of them Haas, Darren is delighted with his choice of brand. “We do intricate work; they are small, high precision parts and our tolerances are often as low as 30 microns. They need to be very smooth. The Haas machines are perfect for the job.”

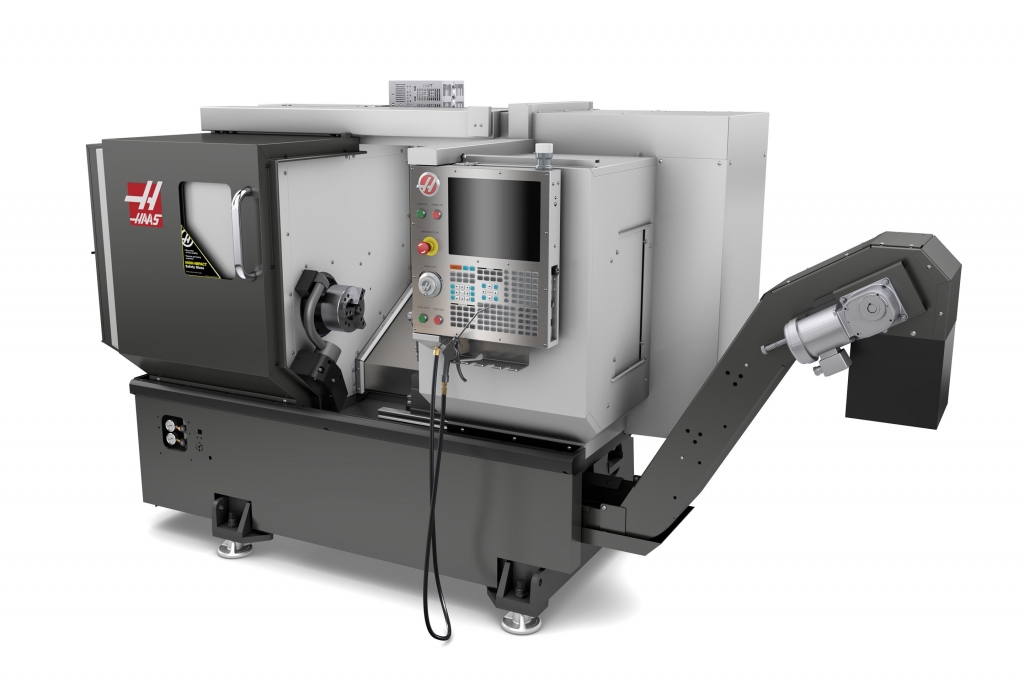

“Each time we buy a new model, from the Mini Mill, to the ST-10 turning centre, Chris comes out and walks us through the purchase. We’ve always had excellent support and full training from Scot Nicolson, our Haas Engineer, who doesn’t leave until he knows we’re confident with the machine.”

Darren uses OneCNC to design most of his products, and Mastercam for 5-axis work. “We wanted a 5-axis machine because we do a lot of 360° engraving. We chose the VF-2 equipped with a Haas TR100 trunnion featuring a 100 mm platter and it’s absolutely brilliant. We’re using fewer operations which has cut our cycle times right down. We mainly do batch work, so it has made a real difference, it’s fantastic.”

“We are really pleased with our Haas machines. They’re extremely reliable; we rarely have a problem. We had one small issue on the SMM-2 which we couldn’t resolve ourselves, but Scot Nicolson came to the rescue and sorted it straight away. He’s a very knowledgeable fellow.”

“All we want to do is to keep expanding, improving our products and our range. We know Haas will help us achieve our goals.”

Today, Hellfire Mods is one of the most sought-after brands in the world of high-end vaping and collectibles. Their success has recently been recognised, scooping the prestigious Best Atomiser trophy at the Eurovape Awards in Spain.

Darren and his daughter with the Best Atomiser trophy awarded to The Attysmith Company at the Eurovape Awards in Spain

“We do intricate work; they are small, high precision parts and our tolerances are often as low as 30 microns. They need to be very smooth. The Haas machines are perfect for the job.”

Darren Lyons – The Attysmith