Wright Engineering Ltd

Nick Wright formed the Wright Engineering Company in 2004, having completed his apprenticeship at the prestigious engineering company Crosthwaite and Gardiner, where he developed his experience in manufacturing components for historic motor racing cars such as Bugatti, Bentley and Aston Martin.

Nick soon established a customer base, supplying precision machined components to the motorsport industry for cars and bikes both classic and modern.

The East Sussex firm has recently designed and built parts used on the yachts taking part in the America’s Cup. This iconic competition, known as ‘Formula 1 On Water’, is the oldest trophy in international sport, dating back to 1851. Nick Wright manufactured the mounts for television and camera equipment used on board the yachts while filming the race.

Wright Engineering’s reputation is based upon a high quality, reliable service. Now with a customer group of over two hundred, the firm is looking to explore niche markets, concentrating on high precision, quality batch work for larger clients.

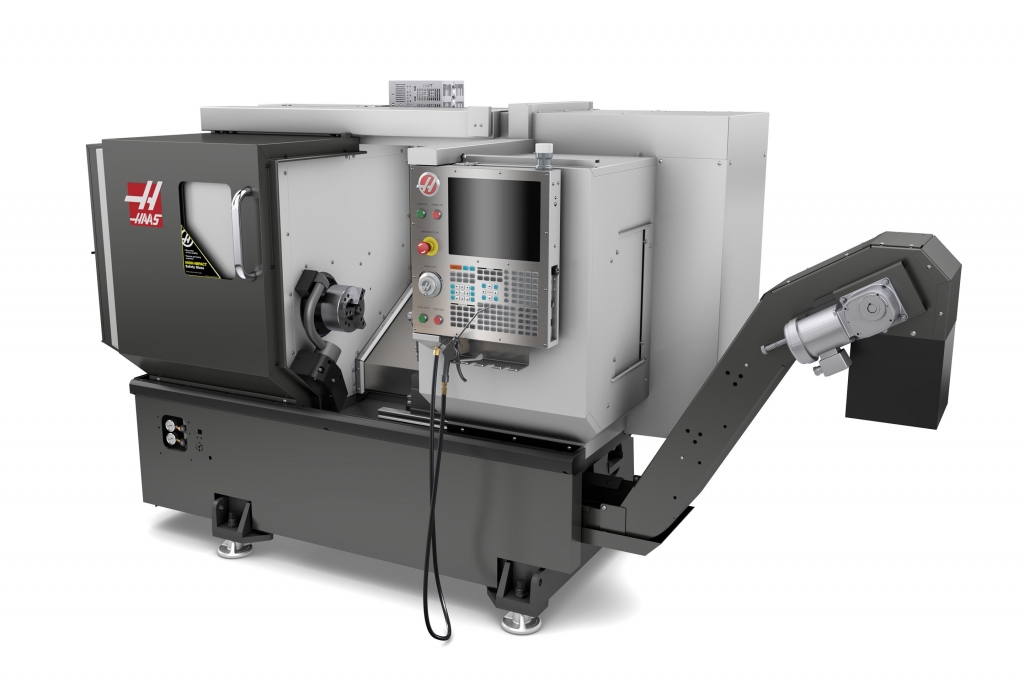

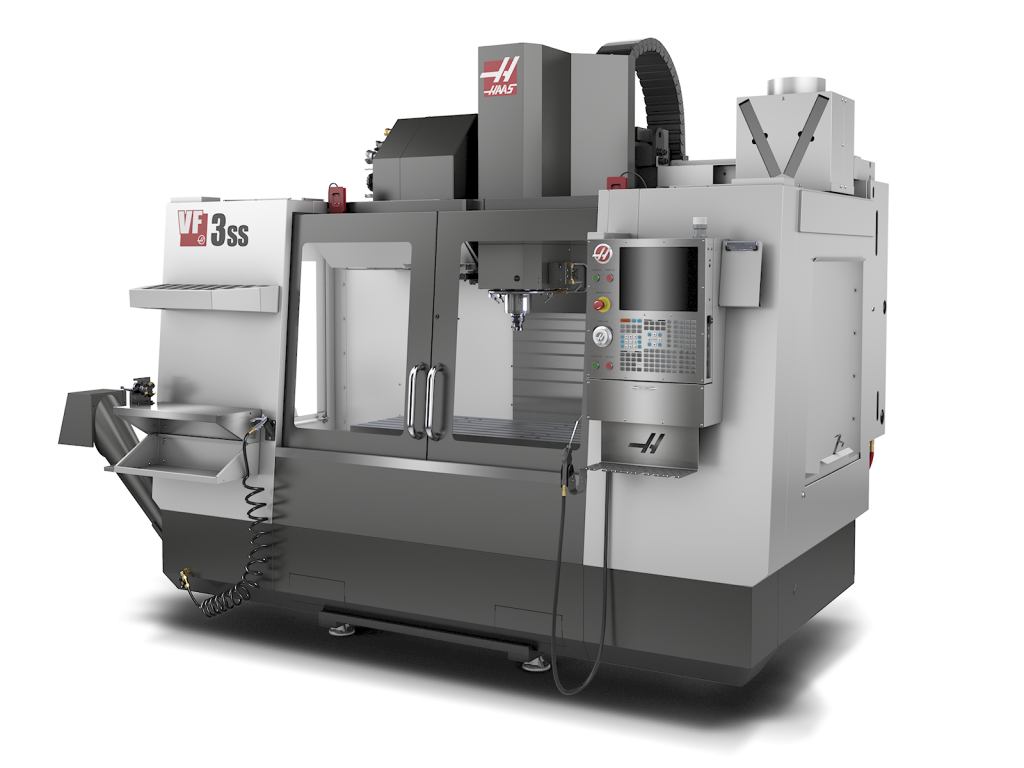

They have four CNC machines, including two Haas VF-3SS Super Speed vertical machining centres and a Haas ST-10 lathe with tailstock.

“We want to replace our other CNC’s with Haas. We have a fantastic relationship with them. They have so many engineers on the road and the supply of spare parts is far better than we have experienced with other suppliers. The ST-10 is the perfect lathe for our workshop. We’re regularly producing batches of around 10 to 50 so we’re constantly loading new jobs, but it’s so quick and easy to do. The machine has massively increased our volume of work as cutting times are down by at least 75%.”

Already familiar with Haas at Crosthwaite and Gardiner, Nick looked to supplier and customer Ryan Goodger at Jota Sport, who already have four machines, to affirm his decision to buy. “Ryan was quick to recommend Haas; making our decision to buy an easy one. Once the machines were installed we had training on site and were making parts straight away. The control is easy to use and the machines are very reliable.”

Machining a wide range of materials, Wright Engineering also has customers in the scientific and medical industries. Their main focus, however, is motorsport and they thrive on solving engineering problems. They work with two wheels as well as four; supporting people like Barry Sheene’s mechanic, Nigel Everett, who restores Moto GP bikes.

In the last two years the company growth has doubled and Nick Wright is confident that “the sky is the limit” working with partners like Haas.

“We would like to be making our own brand of components in the future and working alongside Haas will help us to accomplish this goal.”