Haas Automation offers a range of robots and cobots that improve your manufacturing processes. They deliver high performance, repeatability, and reliability, and are easy to integrate into any production environment.

By automating repetitive tasks, Haas robots and cobots help reduce labour costs and increase throughput. Simple to set up and operate, Haas robots and cobots enhance productivity and keep you competitive.

-

All-inclusive design, with plug-and-play capabilities

-

Interfaces directly with the Haas control

-

All set up and operation is done through the Haas control and remote jog handle

-

Single gripper included

-

Includes CE/UKCA compliant safety guard fencing

-

No need for additional M-code outputs, or the complex PLC connections used by 3rd-party integrators

Video

Haas Cobots – Choosing the Right Platform.

Mike introduces Haas’ new Cobot Kit! You get absolutely amazing value when you purchase this kit along with a new machine. The Haas all-in-one HC10 Machine Ready Cobot kit includes everything required to run your new Cobot right off the Haas control. This kit features the HC10 Cobot with a 10kg part capacity, dual pneumatic grippers, protective barriers, a mounting base, a parts table, and all necessary hardware and cables.

Video

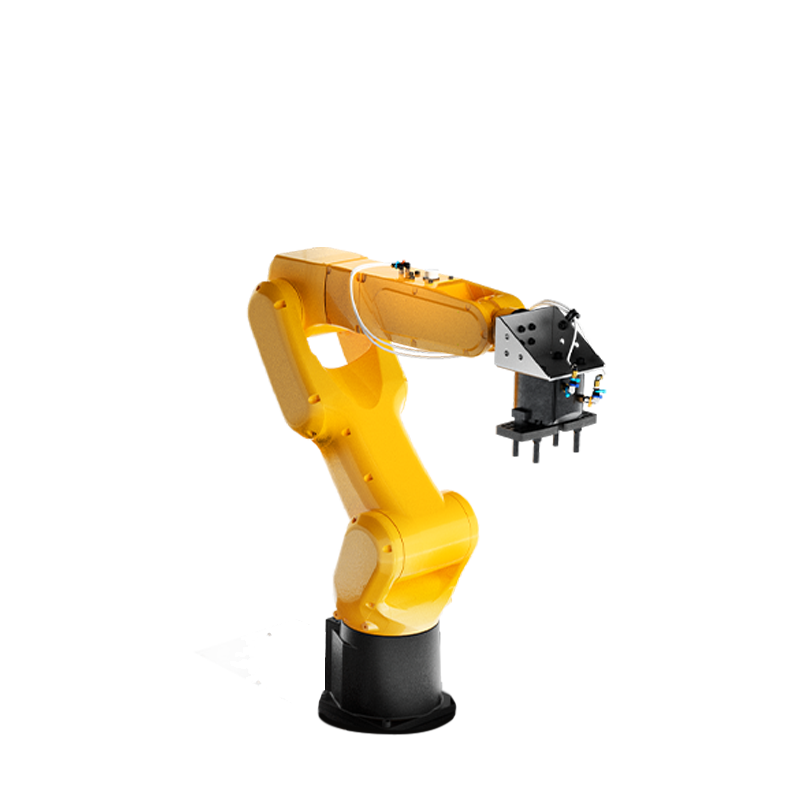

HRP-1, our small-sized plug & play robot system with ST-10Y Y-axis lathe.

What do you get when you combine our small footprint ST-10Y turning centre with our 7 kg robot? The ability to run complex parts unattended all inside a small chunk of real estate.

Video

Automated Machining Cell VS Manually Loaded Machining Cell – Haas Automation.

This 90 second video shows the potential output increase and labour hours decrease when switching to an automated cobot loaded cell from a manually loaded machining cell.

Stay competitive with a Haas plug & play robot system.

Manufacturing Engineer Mallory Tevini is back again showing how robots can help address some of the most common concerns shops have these days. Mallory demonstrated the capabilities of the Haas robot at IMTS. She had the chance to talk to show attendees from all over, and many of those visitors repeated these same three concerns. Check out how a Haas robot can help in each of these cases.

Video

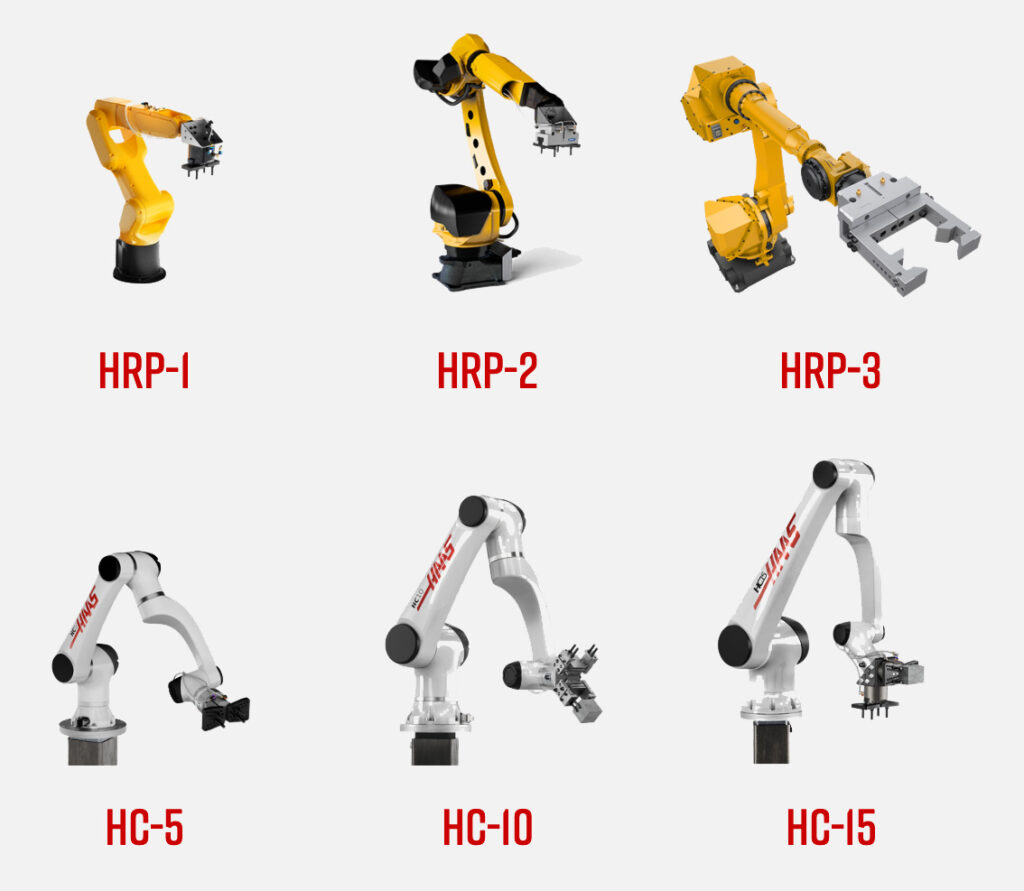

Take a look at the HRP-2, our medium-sized plug & play robot system.

The HRP-2 package includes the 25 kg capacity 6-axis robot, mounting pedestal, software interface for direct control through the Haas machine, electrical interface box, safety guarding, and all necessary solenoids, hardware, and cables. Includes Remote Jog Handle-Touch and Auto Door, when ordered with a machine.

We’re here to answer all of your questions about adding a robot to your shop. Haas robots don’t take up that much space, cost a huge amount of money, or take weeks to integrate. Watch the videos below to learn more.

Space Efficient

Cost Effective

Easy to Integrate

Easy to Learn

See How Customers Around The World Are Using Haas Robots

MASTEQ

AMERICAN TORCH TIP

RAYGINN

PRIMARY MACHINE & REPAIR

KB PRECISION

DYNAMIC MANUFACTURING

We’re here to answer all of your questions about adding a robot or cobot to your shop.

For details email us, or call 01603 760539.

quick reply form

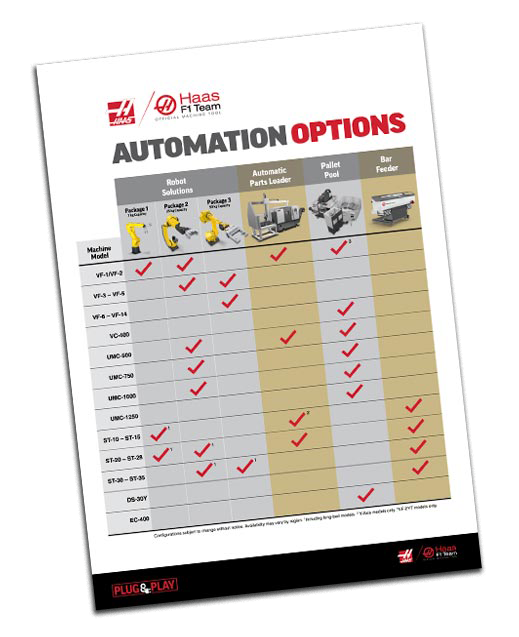

Automation options and configurations chart

See which Robot, Pallet Pool and other automation will fit your Haas machine.

Do you need funding?

Talk to our dedicated team

Haas Financial Services can find you the most competitive funding options from our extensive portfolio of funders.

Navigating your way through the different forms of lending banks and companies have to offer can be hard.

Get in touch and we’ll be able to help you find the perfect option to finance your business and let you take the next step.

For more details on finance packages, please call 01603 227838 or email: finance@haas.co.uk