2K Engineering

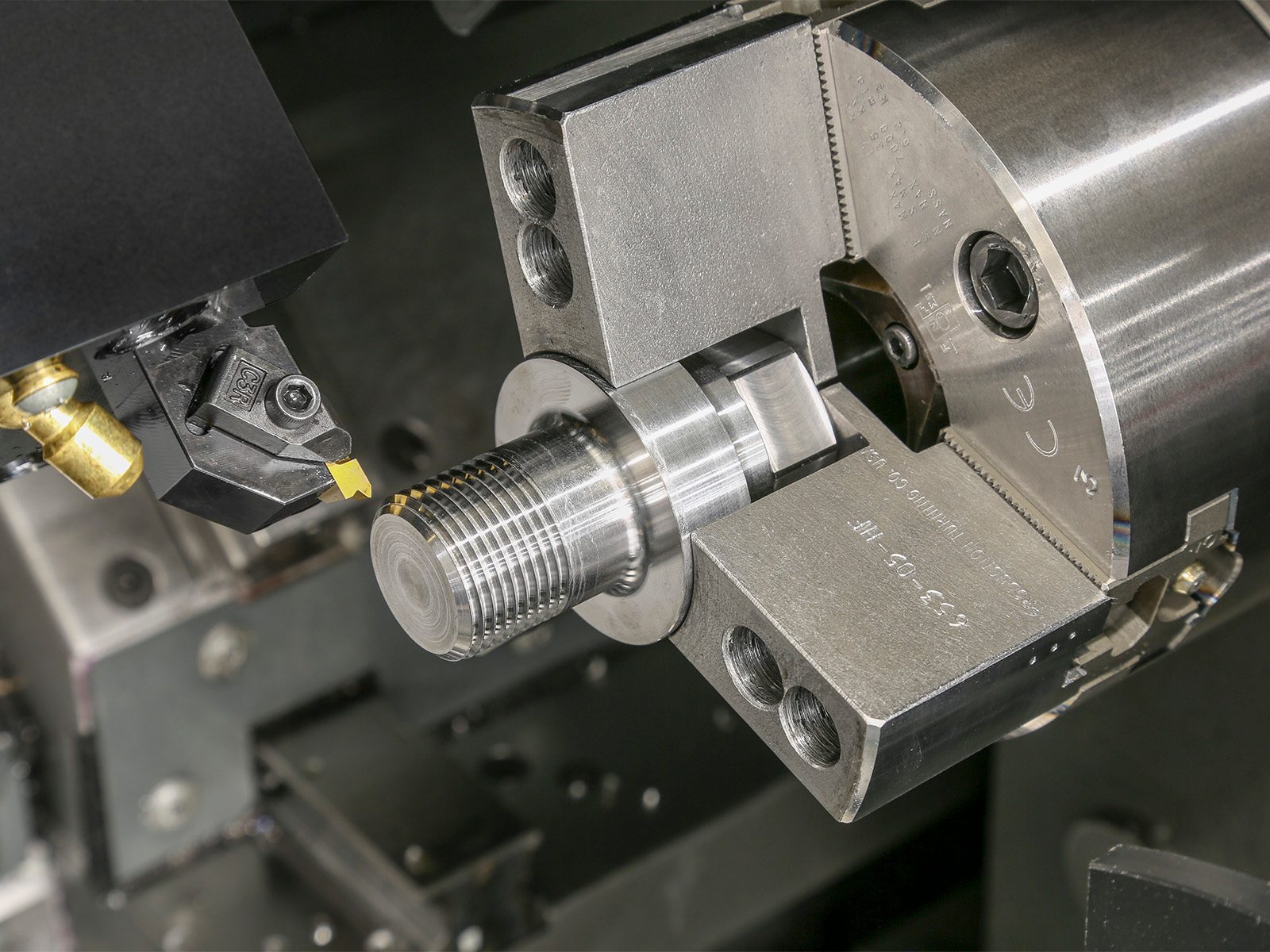

Peterborough based 2K Engineering Limited have just invested in a brand new Haas ST-25Y CNC lathe, with sub-spindle and Y-axis.

The ST-25Y delivers a punch with a 30hp Vector Drive 3,400 rpm A2-6 spindle and a generous 76mm bar capacity through the spindle and a 10” chuck. The BMT65 turret drives a high torque live tooling platform and the machine has the added benefit of a Y axis with +/- 51mm of travel, offering total of 102mm of total Y-axis movement. Even more agility is derived from the 6,000 rpm sub-spindle, offering the benefit of completed parts in one operation.

2K Engineering has been set up in the UK since 2018, but the owners and founders have decades of combined experience machining in Eastern Europe.

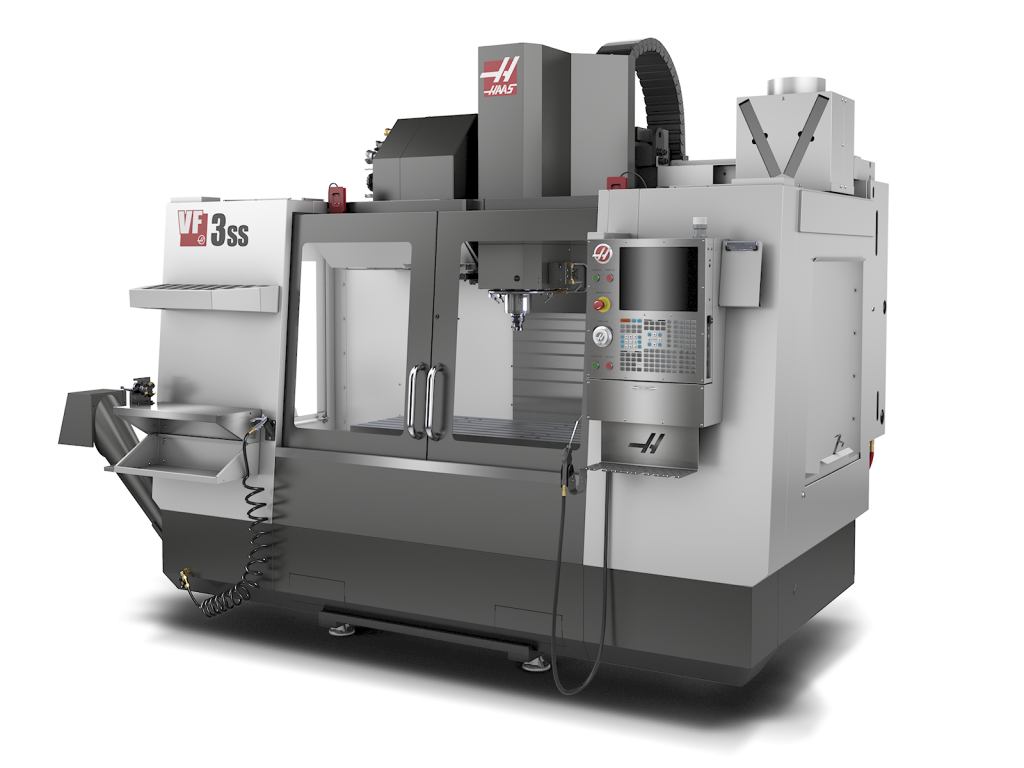

The business already has a great selection of CNC machinery, including a Haas Super Mini Mill 2 and a Haas Super Speed VF-3SS vertical.

Most recently 2K Engineering has been very successfully working directly for F1 teams which is a testament to the quality they produce. They are also able to offer bespoke engineering solutions including prototype design in a wide range of materials.

2K Engineering’s owner & founder said, “We are really excited about this latest investment and very much looking forward to being able to provide Y-axis solutions to new and existing customers. We hope that the added benefit of a sub-spindle will open up more possibilities. We want to be able to offer what many sub-contractors cannot, and the new Haas lathe will allow us to stay ahead of that curve!”

2K Engineering is happy to take enquiries for any machining requirements, take a look at their website here:

“We are really excited about this latest investment and very much looking forward to being able to provide Y axis solutions to new and existing customers. We hope that the added benefit of a sub-spindle will open up more possibilities. We want to be able to offer what many sub-contractors cannot, and the new Haas lathe will allow us to stay ahead of that curve!”

Owner & founder – 2K Engineering